Simulation and experimental studies of hot sizing process for composite wing structures

-

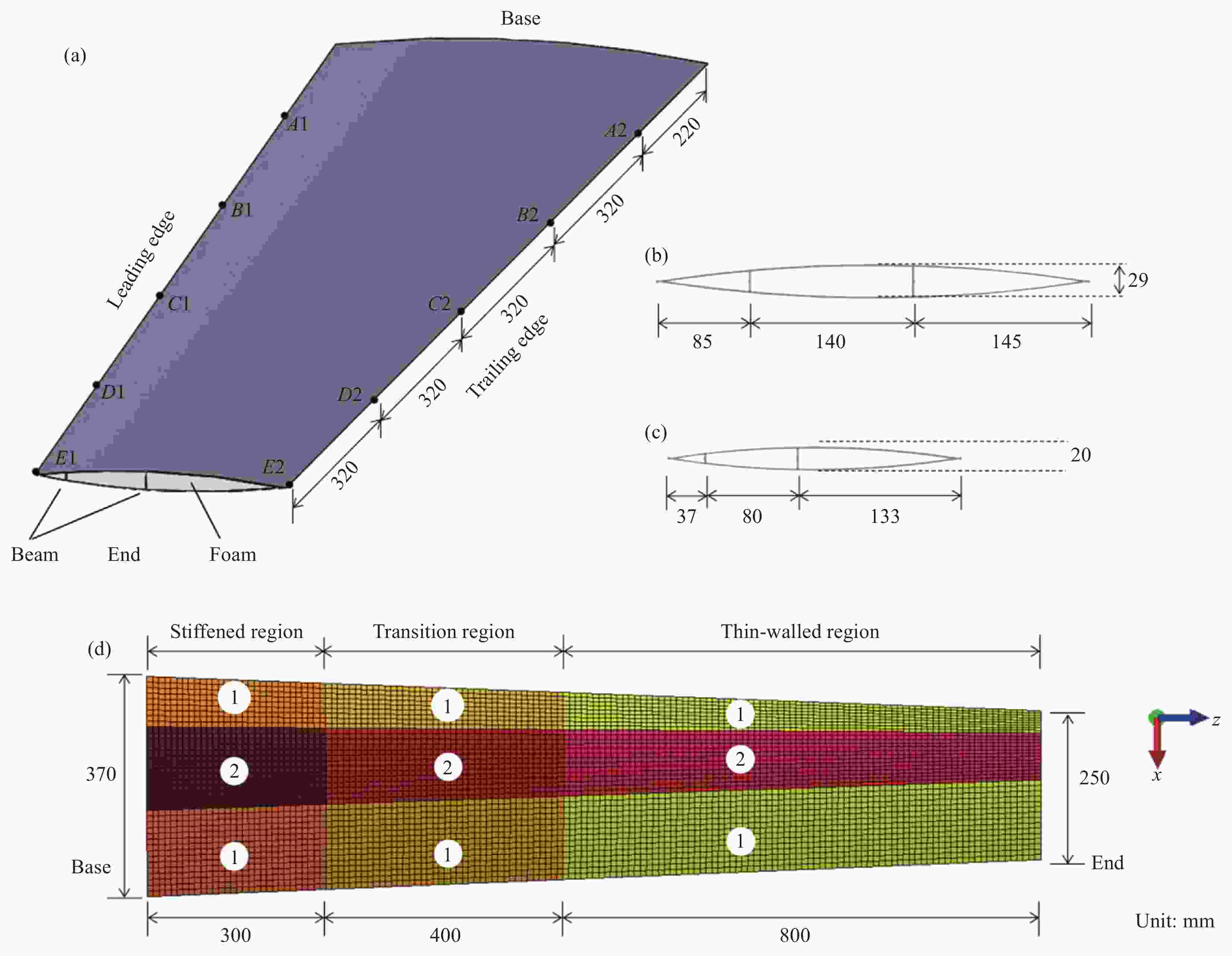

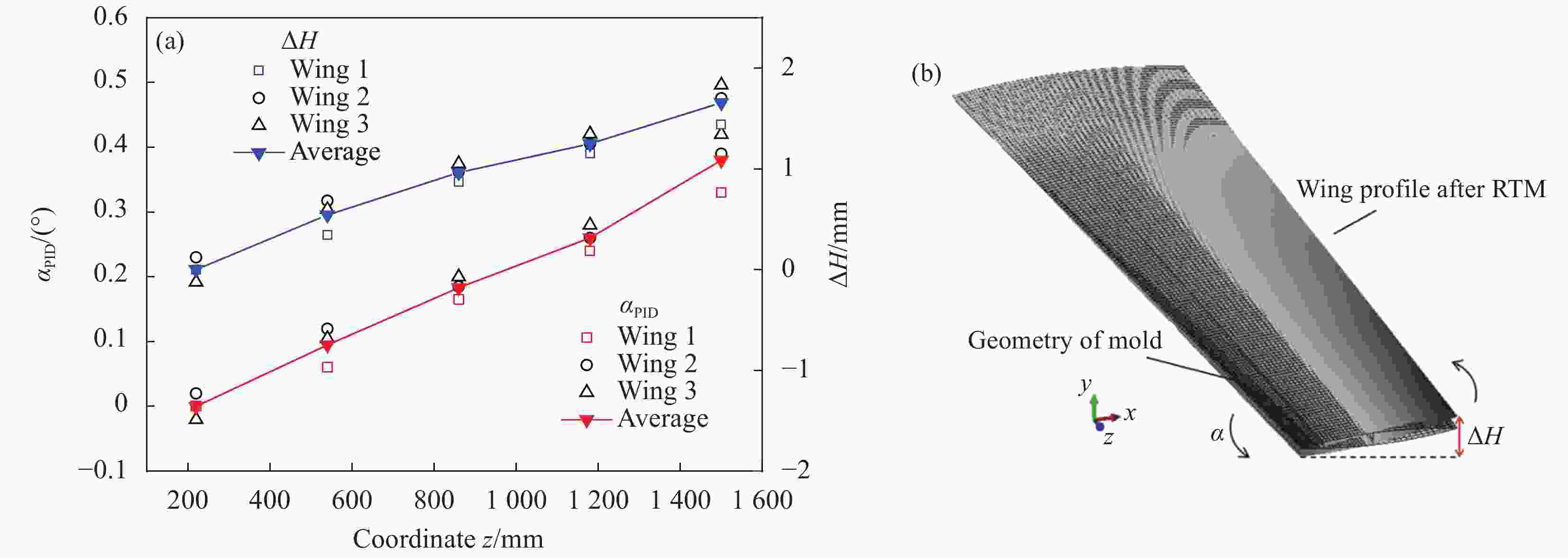

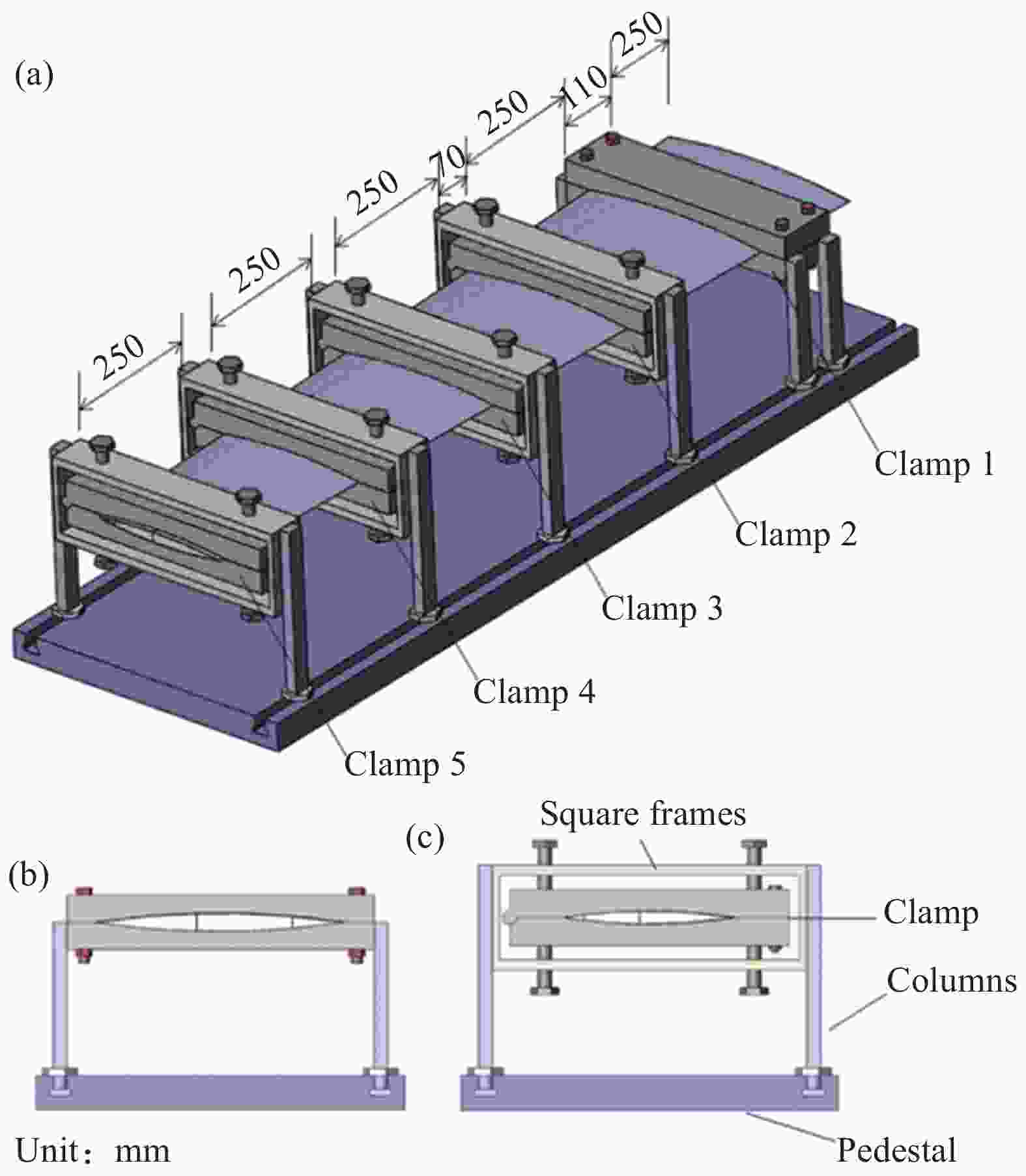

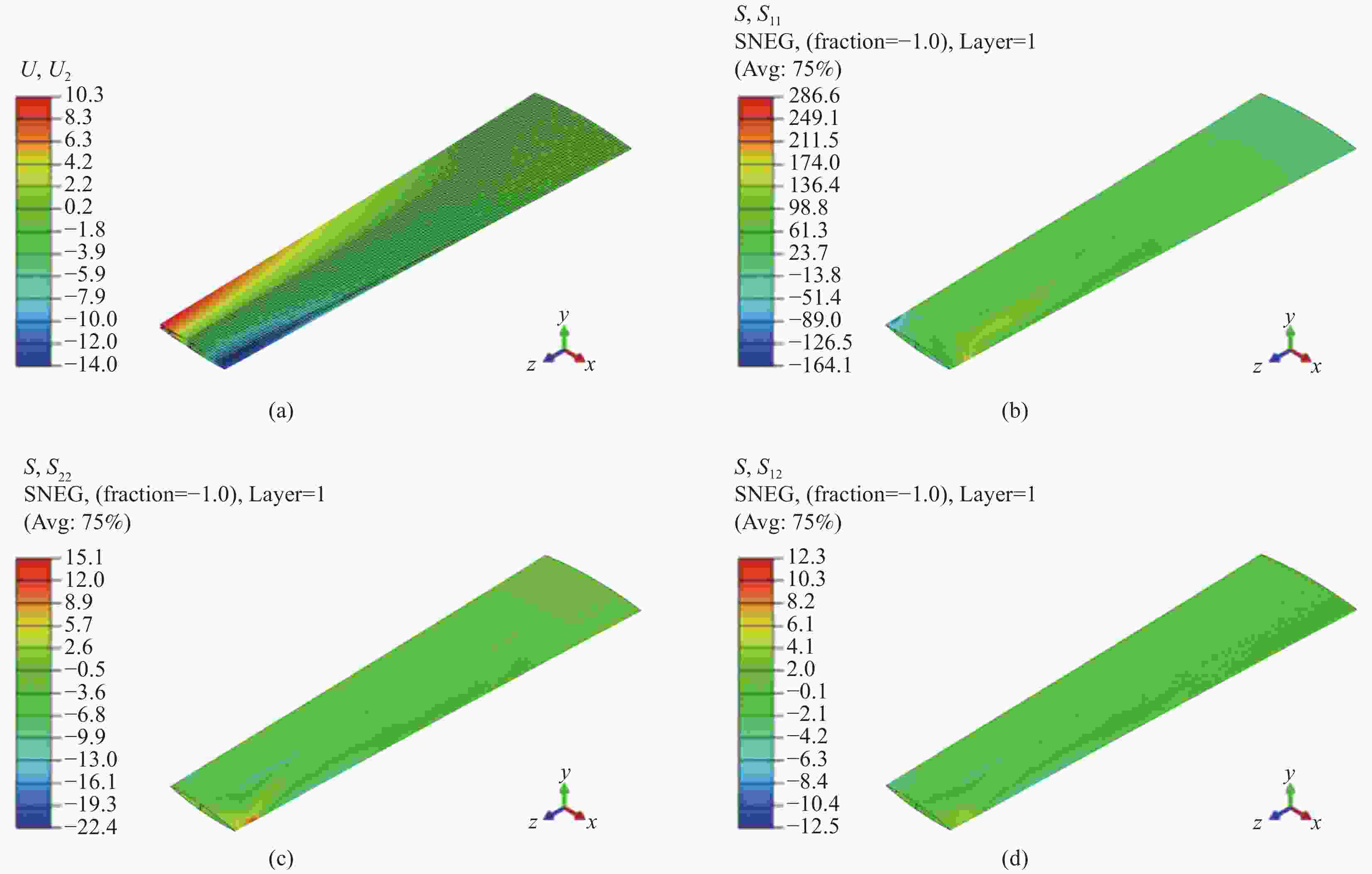

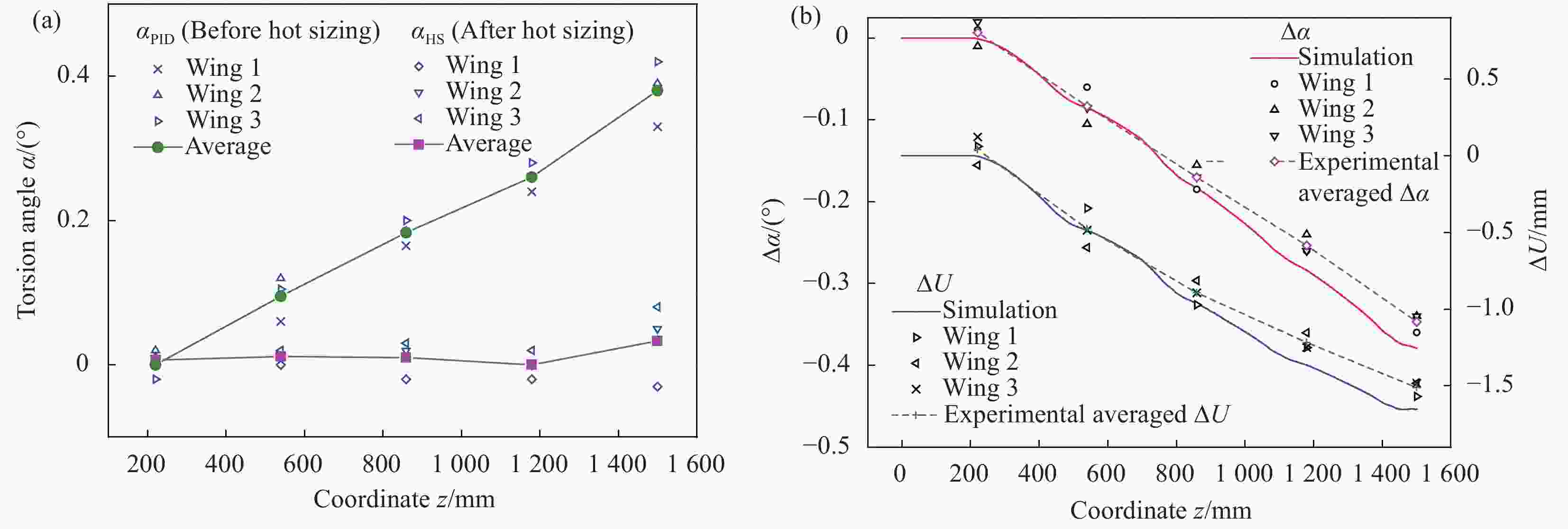

摘要: 纤维增强树脂基复合材料机翼结构复杂,往往存在明显的固化变形现象,严重影响机翼的装配和气动特性。本研究目的在于建立大型复合材料复杂结构的热校形工艺方法,解决复合材料机翼制造的变形控制问题。针对复合材料机翼的固化变形特点,设计了新的热校形夹具工装。在评价复合材料应力松弛特性的基础上,建立了大型复合材料机翼结构热校形工艺的有限元模拟方法,实现了对热校形后机翼结构残余变形的有效预报,分析了校形载荷、校形温度等关键工艺参数对校形效果的影响规律,形成优化的热校形工艺方案。模拟及实验结果表明,复合材料热校形工艺可以适用于大型复杂结构,复合材料机翼89.5%的固化变形被热校形工艺的残余变形抵消,达到机翼的装配和气动外形要求。Abstract: Obvious process induced distortions usually take place in complex wing structures made of polymer-matrix composites. This leads to problems in the assembly and aerodynamics performance of composite wings. The objective of the present work is to develop a hot sizing process for large and complex composite structures, to solve the distortion control problem of composite wings. New sizing tools were designed according to the process induced distortions of wings, to carry out hot sizing experiments. A finite element simulation method was built up to predict the final shape of wings after hot sizing, based on characterizing the stress relaxation property of composites. The effects of process parameters were analyzed including temperature, sizing loads, et al, in order to optimize the hot sizing scheme. The simulation and experiments results show that hot sizing process is valid for large and complex composite structures. 89.5% of the process induced distortions of the composite wing structures is compensated by the hot sizing process, meeting the geometry requirements for assembly and aerodynamic characteristics.

-

Key words:

- composite /

- hot sizing /

- distortion control /

- stress relaxation /

- finite element analysis

-

表 1 T300碳纤维/环氧树脂复合材料力学参数

Table 1. Mechanical parameters of T300 carbon fiber/epoxy composite

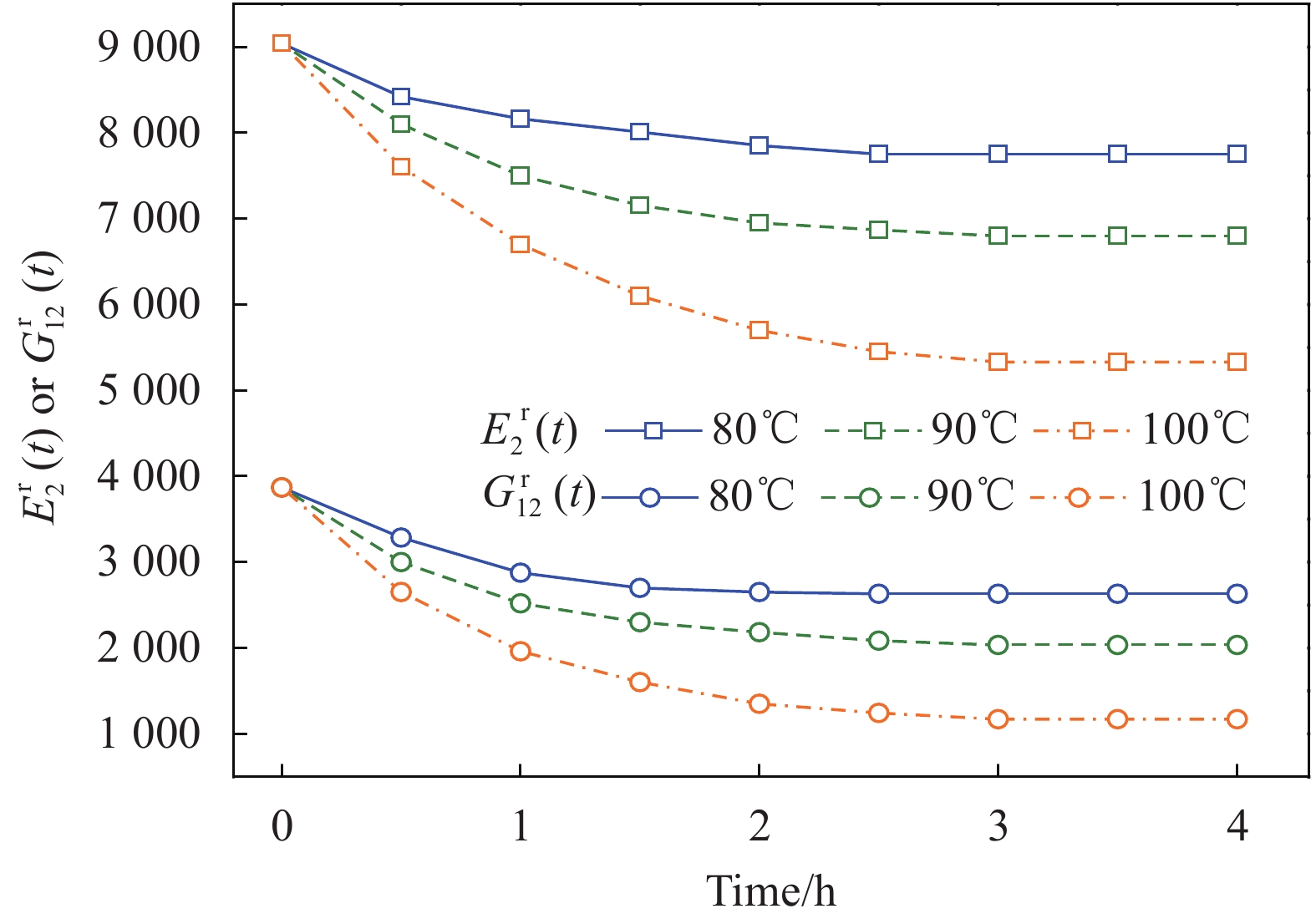

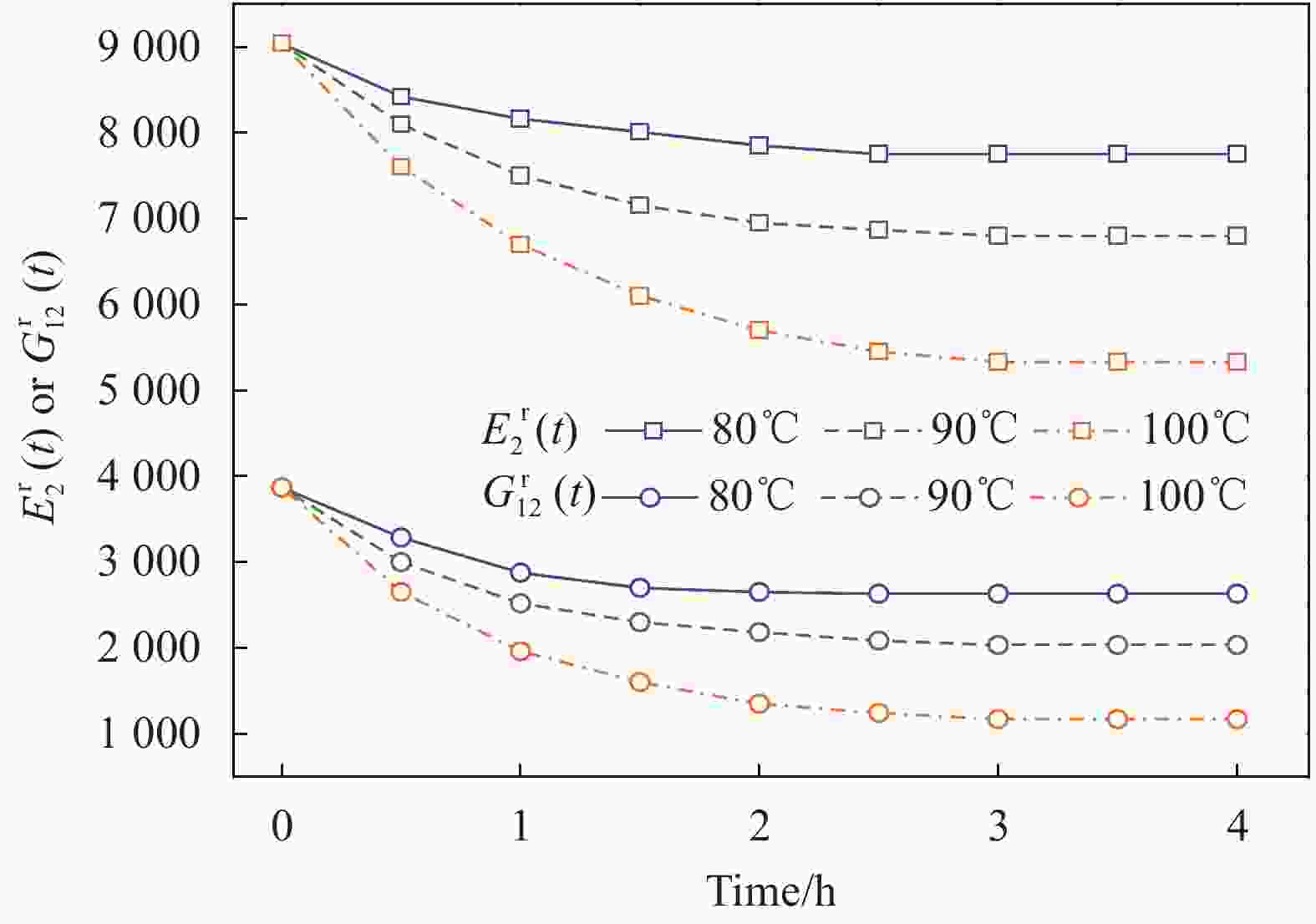

Parameter E11/GPa E22/GPa μ12 G12/GPa G13/GPa G23/GPa Value 136 9.04 0.34 3.87 3.87 3.22 Notes: E11, E22—Modulus in 1st direction and 2nd direction, respectively; μ12—Poisson’s ratio in 12 direction; G12, G13, G23—Shear modulus in 12 direction, 13 direction and 23 direction, respectively. 表 2 机翼结构不同区域铺层情况

Table 2. Stacking sequences of plies in wing

Region Skin area 1 Skin area 2 Beam Stiffened [(45/02/−45)2/(45/03/−45/03)2] [(45/−45/03/45/−45/0)2/(45/02/−45/03/45/02/

−45/0)S/(45/0/0/−45)2/(45/03/−45/03)2][(45/02/−45/03/45/02/−45/90)S/45/

−45/03/45/−45/0]2Transition [45/02/−45/(45/03/−45/03)2] [45/−45/03/45/−45/0/(45/02/−45/03/45/02/

−45/90)S/45/02/−45/(45/03/−45/03)2][45/02/−45/03/45/02/−45/90]SS Thin-walled [45/03/−45/03]2 [(45/02/−45/0/3/45/02/−45/90)S/(45/03/−45/03)2] [(45/02/−45/03/45/02/−45/90)S/45/

−45/03/45/−45/0]表 3 校形载荷Ls和校形温度Ts对热校形工艺回弹率S的影响

Table 3. Effect of hot sizing temperature Ts and sizing loads Ls on spring back rate S

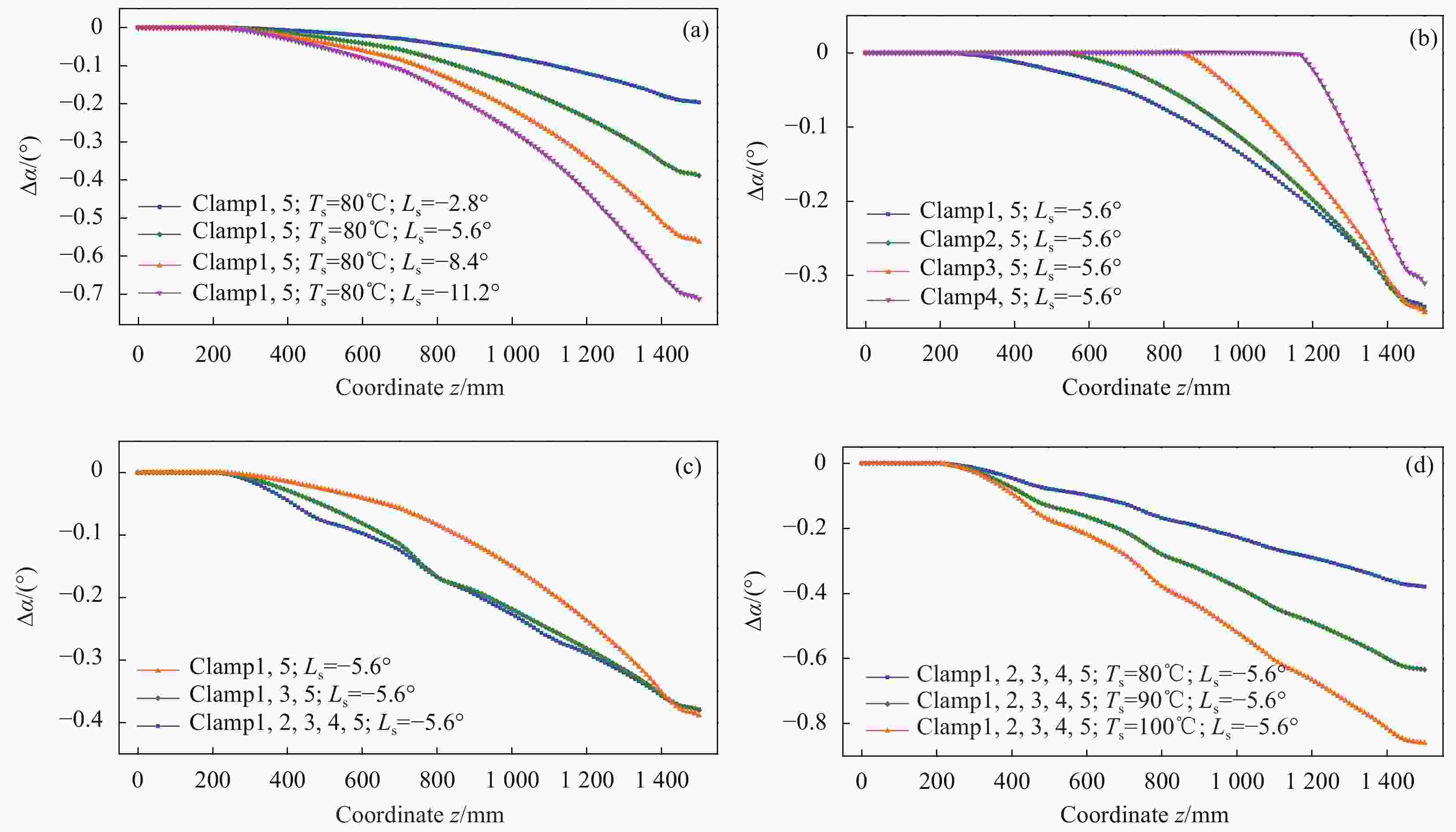

Ls/(°) Ts/°C Δα/(°) S/% −2.8 80 −0.19 93.0 −5.6 80 −0.38 93.1 −8.4 80 −0.56 93.3 −11.2 80 −0.71 93.6 −5.6 80 −0.38 93.2 −5.6 90 −0.63 88.7 −5.6 100 −0.86 84.6 -

[1] 岳广全. 整体化复合材料壁板结构固化变形模拟及控制方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.YUE Guangquan. Study on simulation and control method of cure-induced deformation for integrated composite panel[D]. Harbin: Harbin Institute of Technology, 2010(in Chinese). [2] 李君, 姚学锋, 刘应华, 等. 复合材料T 型整体化结构固化翘曲变形模拟[J]. 复合材料学报, 2009, 26(1):156-161. doi: 10.3321/j.issn:1000-3851.2009.01.027LI Jun, YAO Xuefeng, LIU Yinghua, et al. Simulation on curing warpage deformation of composite T-shaped integrated structure[J]. Acta Materiae Compositae Sinica,2009,26(1):156-161(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.01.027 [3] 江天, 徐吉峰, 刘卫平, 等. 整体化复合材料结构分阶段固化变形预报方法及其实验验证[J]. 复合材料学报, 2013, 30(5):61-66. doi: 10.3969/j.issn.1000-3851.2013.05.010JIANG Tian, XU Jifeng, LIU Weiping, et al. Simulation and verification of cure-induced deformation by stages for integrated composite structure[J]. Acta Materiae Compositae Sinica,2013,30(5):61-66(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.05.010 [4] WU B, LAN F, PARDOEN T, et al. Tooling geometry optimization for compensation of cure-induced distortions of a curved carbon/epoxy C-spar[J]. Composites Part A: Applied Science and Manufacturing, 2014, 56: 27-35. [5] LIU K, YE J, TANG Z, et al. Simulation and verification of machining deformation for composite materials[J]. Journal of Wuhan University of Technology (Materials Science Edition), 2014, 29(5): 917-922. [6] DING A, LI S, WANG J, et al. A three-dimensional thermo-viscoelastic analysis of process-induced residual stress in composite laminates[J]. Composite Structure,2015,129:60-69. [7] ISMET B, KENAN C, NURI E, et al. A review on the mechanical modeling of composite manufacturing processes[J]. Archives of Computational Methods in Engineering,2016,24(2):1-31. [8] BRAUNER C, BAUER S, HERRMANN A S. Analysing process-induced deformation and stresses using a simulated manufacturing process for composite multispar flaps[J]. Journal of Composite Materials,2015,49(4):387-402. doi: 10.1177/0021998313519281 [9] 张纪奎, 郦正能, 关志东, 等. 热固性复合材料固化过程三维有限元模拟和变形预测[J]. 复合材料学报, 2009, 26(1):174-178. doi: 10.3321/j.issn:1000-3851.2009.01.030ZHANG Jikui, LI Zhengneng, GUAN Zhidong, et al. Three-dimensional finite element simulation and prediction for process-induced deformation of thermoset composites[J]. Acta Materiae Compositae Sinica,2009,26(1):174-178(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.01.030 [10] LI D, LI X, DAI J. Process modelling of curing process-induced internal stress and deformation of composite laminate structure with elastic and viscoelastic models[J]. Applied Composite Materials,2018,25(3):527-544. doi: 10.1007/s10443-017-9633-5 [11] HO K C, LIN J, DEAN T A. Modelling of springback in creep forming thick aluminum sheets[J]. International Journal of Plasticity. 2004, 20(4-5): 733-751. [12] SHONG Z C, LING Z R, PEKLENIK J. A study of the hot sizing and high temperature mechanical behaviour for titanium alloy sheet[J]. CIRP Annals, 1983, 32(1): 161-165. [13] 陈春奎, 黄永坚, 王以璠, 等. 钛和钛合金钣金零件的热校形[J]. 材料科学与工艺, 1985, 21(2):93-104.CHEN Chunkui, HUANG Yongjian, PAN Yifan, et al. Hot sizing on Ti alloy and Ti parts[J]. Material Science and Engineering,1985,21(2):93-104(in Chinese). [14] ZHAN L, LIN J, DEAN T A. A review of the development of creep age forming: Experimentation, modeling and applications[J]. International Journal of Machine Tools & Manufacture, 2011, 51(1): 1-17. [15] LIN J, HO K C, DEAN T A. An integrated process for modeling of precipitation hardening and spring back in creep age forming[J]. International Journal of Machine Tools & Manufacture, 2006, 46(11): 1266 -1270. [16] HO K C, LIN J, DEAN T A. Constitutive modelling of primary creep for age forming an aluminium alloy[J]. Journal of Materials Processing Technology, 2004, 153-154: 122 -127. [17] AARON C L, SHI Z, YANG H, et al. Creep-age forming AA2219 plates with different stiffener designs and pre-form age conditions: Experimental and finite element studies[J]. Journal of Materials Processing Technology, 2015, 219: 155-163. [18] LEI C, YANG H, LI H, et al. Dependence of creep age formability on initial temper of an Al-Zn-Mg-Cu alloy[J]. Chinese Journal of Aeronautics,2016,29(5):1445-1454. doi: 10.1016/j.cja.2016.04.022 [19] LIU K, YE J, ZHANG B, et al. Experimental and finite element studies on hot sizing process for L-shaped composite beams[J]. Composites Part A: Applied Science and Manufacturing, 2016, 87: 161-169. [20] ASTM International. Standard test methods for tensile, compressive, and flexural creep and creep-rupture of plastics: ASTM D2990—17[S]. West Conshohocken: ASTM International, 2017. [21] SUN C T, CHEN J L. A simple flow rule for characterizing nonlinear behavior of fiber composites[J]. Journal of Composite Materials, 1989, 23(10): 1009–1020. [22] LI H, ZHANG B. A new viscoelastic model based on generalized method of cells for fiber-reinforced composites[J]. International Journal of Plasticity, 2015, 65: 22-32. -

下载:

下载: