| [1] |

邓本诚, 李俊山. 橡胶塑料共混改性[M]. 北京: 中国石化出版社, 1996.DENG Bencheng, LI Junshan. Rubber plastic blending and modification[M]. Beijing: China Petrochemical Press, 1996(in Chinese).

|

| [2] |

LU Y, LIU L, YANG C, et al. The morphology of zinc dimethacrylate reinforced elastomers investigated by SEM and TEM[J]. European Polymer Journal,2005,41(3):577-588. doi: 10.1016/j.eurpolymj.2004.10.019

|

| [3] |

MENG Y, WEI Z, LU Y L, et al. Structure, morphology, and mechanical properties of polysiloxane elastomer composites prepared by in situ polymerization of zinc dimethacrylate[J]. Express Polymer Letters,2012,6(11):882-894. doi: 10.3144/expresspolymlett.2012.94

|

| [4] |

WANG Y, CHEN Z, DING J, et al. Preparation and properties of peroxide dynamically vulcanized poly(vinylidene fluoride)/silicone rubber/zinc dimethacrylate composites[J]. Polymer Composites,2016,37(4):1093-1100. doi: 10.1002/pc.23271

|

| [5] |

伍社毛, 卢咏来, 刘力. 原位聚合纳米PZDMA补强POE 材料的研究[J]. 橡胶工业, 2002, 49(12):709-715.WU Shemao, LU Yonglai, LIU Li. In-site polymerization of nano-PZDMA/POE composite[J]. Rubber Industry,2002,49(12):709-715(in Chinese).

|

| [6] |

GAO G, ZHANG Z, ZHENG Y, et al. Effect of magnesium methacrylate and zinc methacrylate on bond properties of thermal insulation material based on NBR/EPDM blends[J]. Journal of Applied Polymer Science,2009,113 (6):3901-3909. doi: 10.1002/app.30415

|

| [7] |

NIE Y, HUANG G, QU L, et al. Cure kinetics and morphology of natural rubber reinforced by the in situ polymerization of zinc dimethacrylate[J]. Journal of Applied Polymer Science,2010,115 (1):99-106. doi: 10.1002/app.31045

|

| [8] |

CHEN Y, XU C, CAO L, et al. PP/EPDM-based dynamically vulcanized thermoplastic olefin with zinc dimethacrylate: Preparation, rheology, morphology, crystallization and mechanical properties[J]. Polymer Testing,2012,31 (6):728-736. doi: 10.1016/j.polymertesting.2012.05.010

|

| [9] |

CHEN Y, XU C. Stress- strain behaviors and crosslinked networks studies of natural rubber-zinc dimethacrylate composites[J]. Journal of Macromolecular Science Part B: Physics,2012,51(7):1384-1400. doi: 10.1080/00222348.2011.629904

|

| [10] |

LI C, YUAN Z, YE L. Facile construction of enhanced multiple interfacial interactions in EPDM/zinc dimethacrylate (ZDMA) rubber composites: Highly reinforcing effect and improvement mechanism of sealing resilience[J]. Composites Part A: Applied Science and Manufacturing,2019,126:105580.

|

| [11] |

XU C, CHEN Y, WANG Y, et al. Temperature dependence of the mechanical properties and the inner structures of natural rubber reinforced by in situ polymerization of zinc dimethacrylate[J]. Journal of Applied Polymer Science, 2013, 128(4): 2350-2357.

|

| [12] |

郑元锁, 宋月贤, 黄振东. 芳纶短纤维对丁腈橡胶的增强作用[J]. 西安交通大学学报, 1998, 32(8):81-84.ZHENG Yuansuo, SONG Yuexian, HUANG Zhengdong. Reinforcement effect of aramid short fiber on nitrile rubber[J]. Journal of XianJiaotong University,1998,32(8):81-84(in Chinese).

|

| [13] |

刘元顺, 李大宇. 纤维增强的新型高模量液体硅橡胶[J]. 世界橡胶工业, 2014, 41(6):22-25.LIU Yuansun, LI Dayu. New high modulus liquid silicone elastomer fiber-reinforced LSR[J]. World Rubber Industry,2014,41(6):22-25(in Chinese).

|

| [14] |

武卫莉, 于涛. 碳纤维/硅橡胶/氟橡胶复合材料的制备[J]. 橡胶工业, 2018, 65(2):161-166.WU Weili, YU Tao. Preparation of carbon fiber/silicone rubber/fluoro rubber composite[J]. Rubber Industry,2018,65(2):161-166(in Chinese).

|

| [15] |

PARK E S. Mechanical properties and processibilty of glass-fiber-, wollastonite-, and fluoro-rubber-reinforced silicone rubber composites[J]. Journal of Applied Polymer Science,2007,105(2):460-468. doi: 10.1002/app.26063

|

| [16] |

VEARICK S B, DEMÉTRIO K B, XAVIERC R G, et al. Fiber-reinforced silicone for tracheobronchial stents: An experimental study[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2018, 77: 494-500.

|

| [17] |

PRAVEEN S, CHAKRABORTY B C, JAYENDRAN S, et al. Effect of filler geometry on viscoelastic damping of graphite/aramid and carbon short fiber-filled SBR composites: A new insight[J]. Journal of Applied Polymer Science,2009,111(1):264-272. doi: 10.1002/app.29064

|

| [18] |

KASHANI M R. Aramid-short-fiber reinforced rubber as a tire tread composite[J]. Journal of Applied Polymer Science,2009,113(2):1355-1363. doi: 10.1002/app.30026

|

| [19] |

SHIBULAL G S, NASKAR K. RFL coated aramid short fiber reinforced thermoplastic elastomer: Mechanical, rheological and morphological characteristics[J]. Journal of Polymer Research,2011,18(6):2295-2306. doi: 10.1007/s10965-011-9643-1

|

| [20] |

HINTZE C, STOČEK R, HORST T, et al. Dynamic behavior of short aramid fiber-filled elastomer composites[J]. Polymer Engineering and Science,2014,54(12):2958-2964. doi: 10.1002/pen.23854

|

| [21] |

GAO J, YANG X, HUANG L H. Numerical prediction of mechanical properties of rubber composites reinforced by aramid fiber under large deformation[J]. Composite Structures,2018,201:29-37.

|

| [22] |

HE X, SHI X, HOCH M, et al. Mechanical properties of aramid fiber and carbon black filled hydrogenated nitrile rubber for packer compounds[J]. Polymer Composites,2018,39(9):3213-3226.

|

| [23] |

GAO J, YANG Z. Study of the viscoelasticity of chopped aramid fiber reinforced rubber composite[J]. Key Engineering Materials Online,2019,827(1):385-391.

|

| [24] |

ZHANG B, JIANG Y. Preparation of grephene@waterborne polyurethane microcapsules for improving mechanical and interface properties of aramid fibers/natural rubber composites[J]. Composite Interfaces,2019,26(7):571-583. doi: 10.1080/09276440.2018.1514146

|

| [25] |

WEI Z, LU Y, MENG Y, et al. Study on wear, cutting and chipping behaviors of hydrogenated nitrile butadiene rubber reinforced by carbon black and in-situ prepared zinc dimethacrylate[J]. Journal of Applied Polymer Science,2012,124(6):4564- 4571.

|

| [26] |

SHIRAZI M, TALMA A G, NOORDERMEER J W M. Viscoelastic properties of short aramid fibers-reinforced rubbers[J]. Journal of Applied Polymer Science, 2013, 128(4): 2255-2261.

|

| [27] |

RAJA S N, BASU S, LIMAYE A M, et al. Strain-dependent dynamic mechanical properties of Kevlar to failure: Structural correlations and comparisons to other polymers[J]. Materials Today Communications,2015,2:33-37.

|

| [28] |

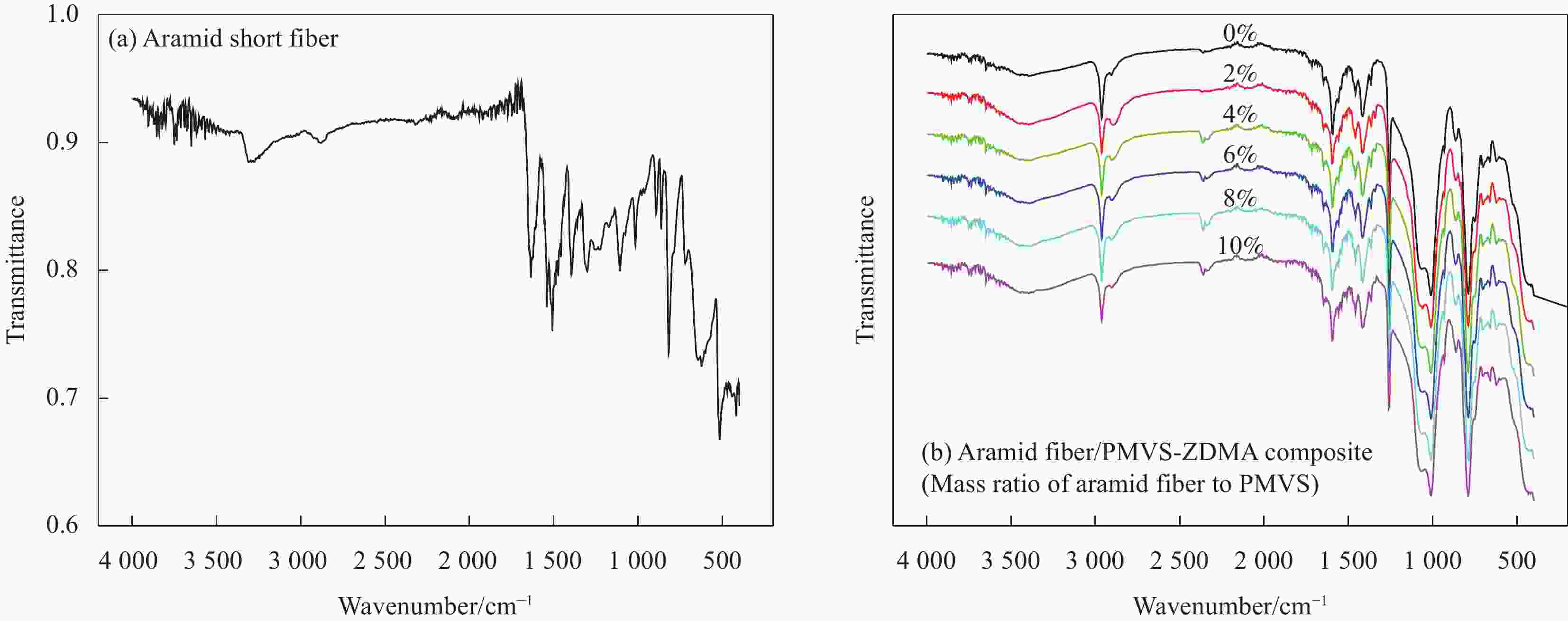

张贤淼, 董激文. 利用FTIR-ATR快速鉴别几种常见产业用纤维[J]. 产业用纺织品, 2015(9): 31-35.ZHANG Xianmiao, DONG Jiwen. Rapid identification of several common industrial fibers with FTIR-ATR[J]. Technical Textiles, 2015(9): 31-35(in Chinese).

|

| [29] |

陈国强. 国产对位芳纶纤维分子结构分析[J]. 山东纺织科技, 2015(3): 49-52.CHEN Guoqiang. Analysis of domestic para-aramid molecular structure[J]. Shandong Textile Science & Technology, 2015(3): 49-52(in Chinese).

|

下载:

下载: