Acoustic emission-based sound velocity characteristics of ceramic matrix composites

-

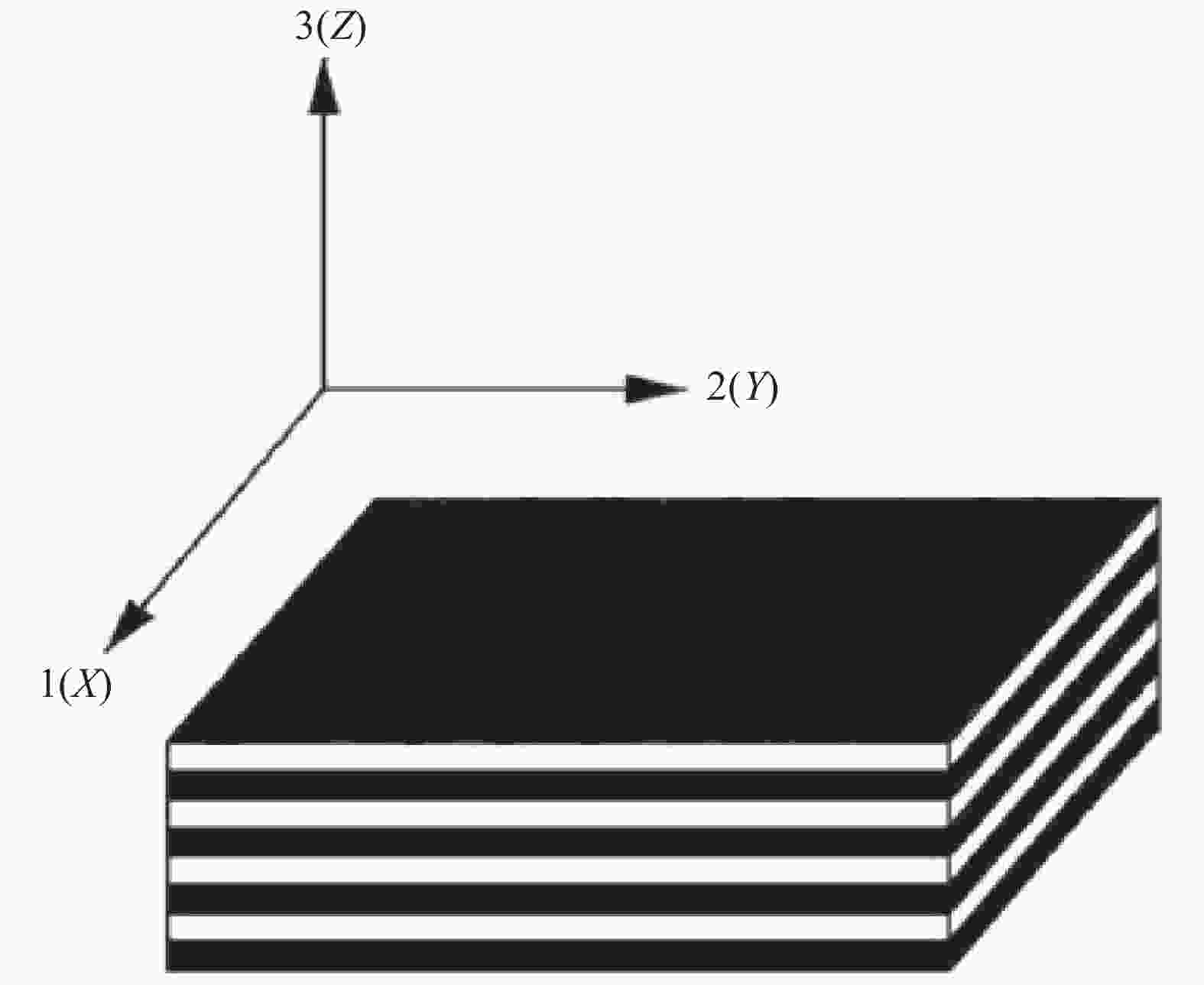

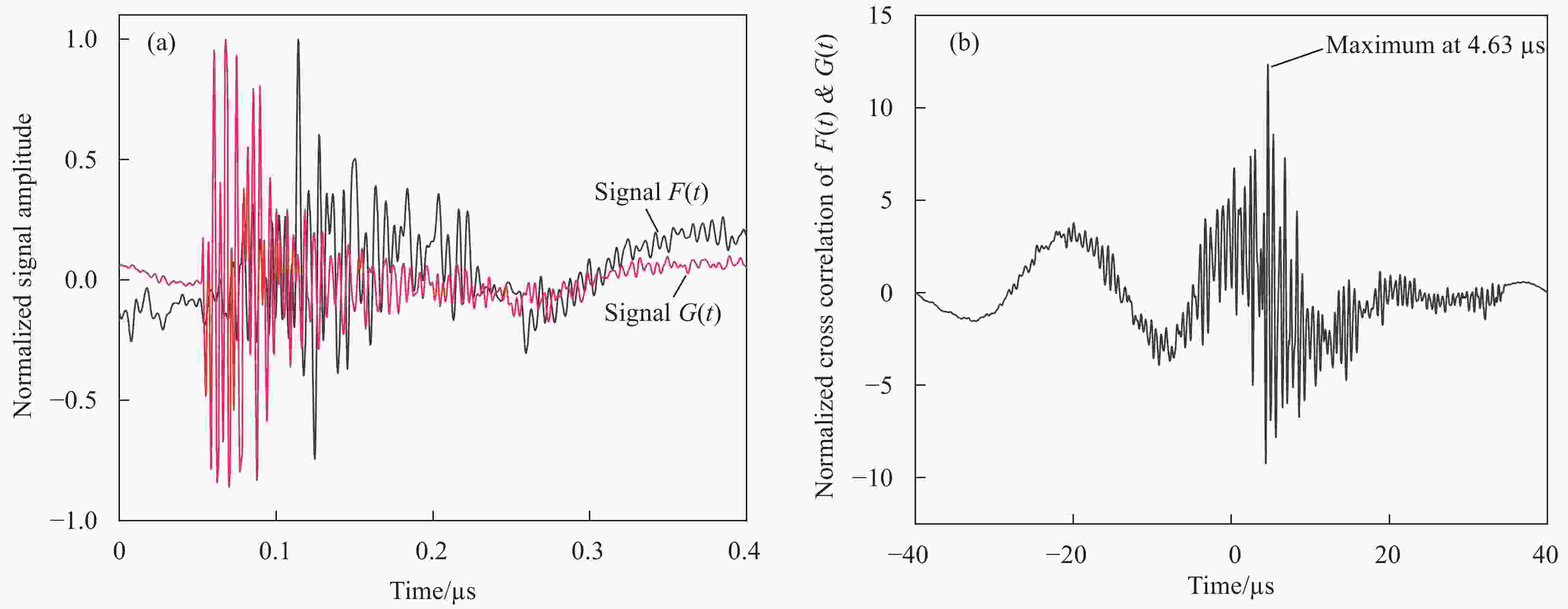

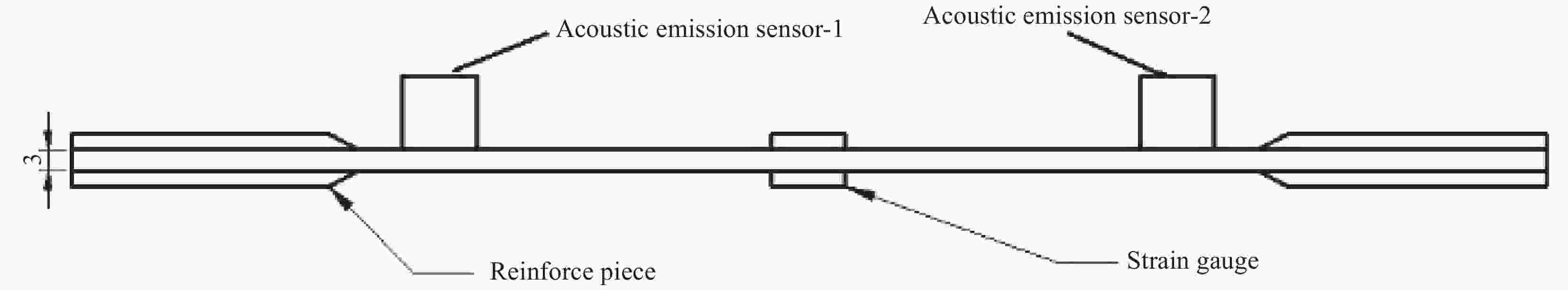

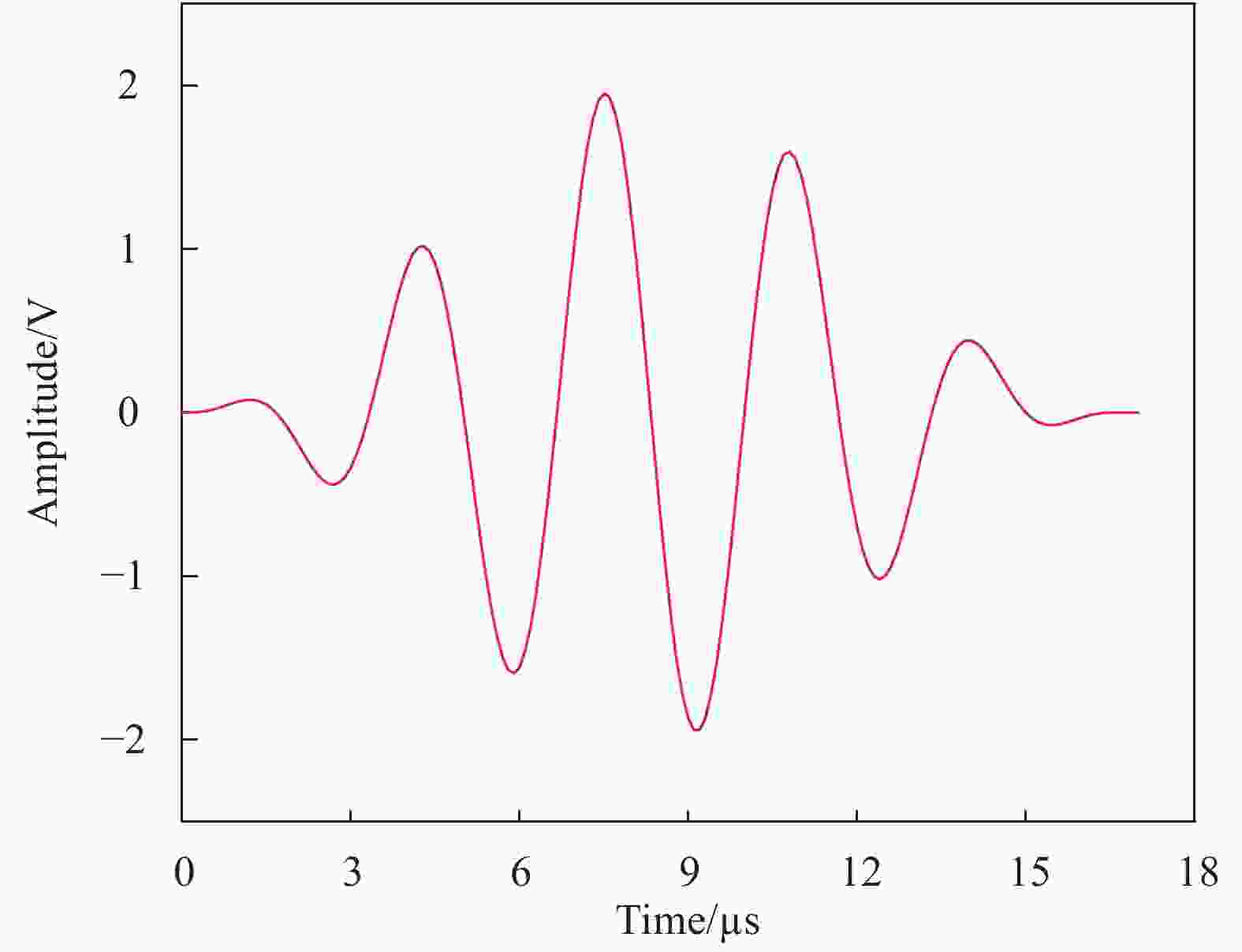

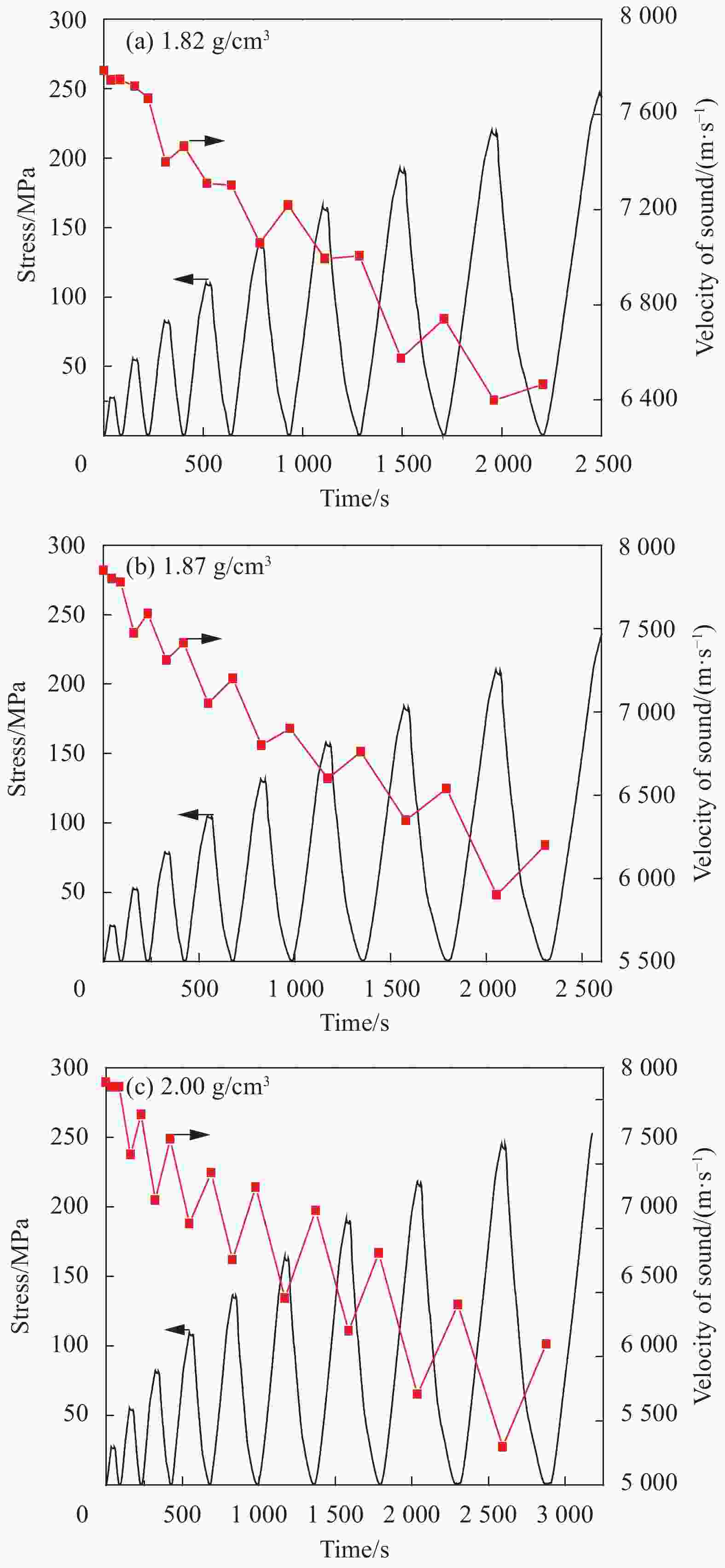

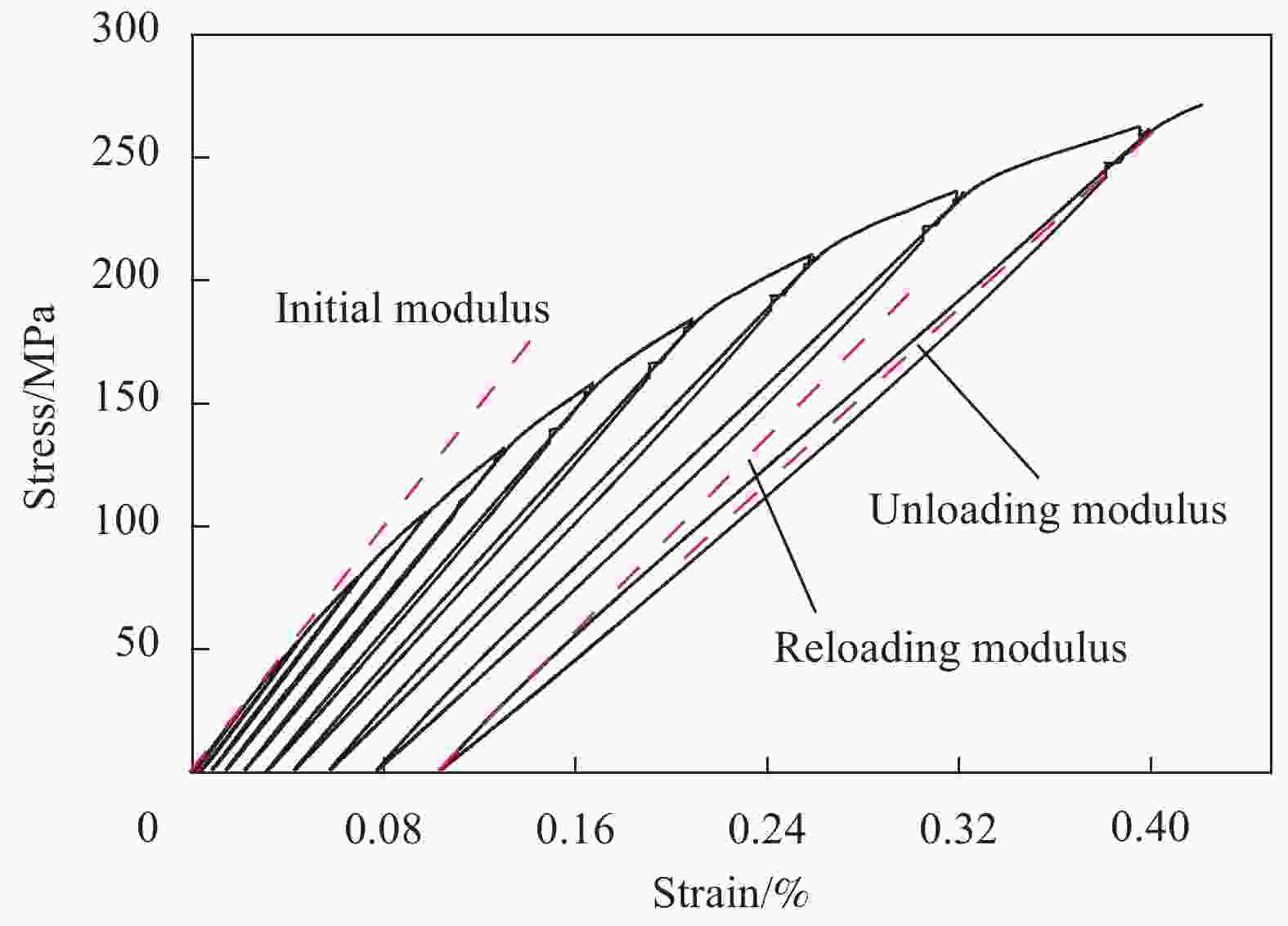

摘要: 基于Christoffel方程,运用复合材料刚度矩阵与弹性常数间的关系,将正交各向异性模型运用于2D-C/SiC复合材料的声学特性中,得到材料声速的表达式。通过循环加卸载试验测量了2D-C/SiC复合材料整个拉伸过程中不同应力水平处的声速变化,研究了声速对2D-C/SiC复合材料的损伤表征。研究发现,随着应力水平的不断增加,声速逐渐下降,2D-C/SiC复合材料损伤程度对声波在材料中的传播速度有较大影响;引入卸载模量和再加载模量,代替声速理论计算切线模量,理论结果与试验结果吻合良好,误差随载荷增加而增大;声波速度随2D-C/SiC复合材料损伤而发生衰减的关系,根据此衰减关系建立了基于声速的损伤表征量。

-

关键词:

- 2D-C/SiC复合材料 /

- 声发射 /

- 损伤 /

- 机制 /

- 声波速度

Abstract: Based on the Christoffel equation, using the relationship between the composite stiffness matrix and the elastic constant, the orthotropic model was applied to the acoustic properties of 2D-C/SiC composites, and the expression of the material sound velocity was obtained. Through the cyclic loading and unloading test, the sound velocity changes at different stress levels during the entire tensile process were measured. The damage characterization of the sound velocity on the 2D-C/SiC composite was studied. The results show that as the stress level continues to increase, the sound velocity gradually decreases, and the material The degree of damage has a greater impact on the propagation speed of sound waves in the 2D-C/SiC composite; the unloading modulus and reloading modulus are introduced to replace the sound velocity theory to calculate the tangent modulus. It is found that the theoretical results are in good agreement with the test results, and the error increases with the increase of load; The sound wave velocity decreases with the damage of the 2D-C/SiC composite, and based on this attenuation relationship, the damage characterization based on the sound velocity was established.-

Key words:

- 2D-C/SiC composites /

- acoustic emission /

- damage /

- mechanism /

- acoustic wave velocity

-

表 1 试验测得的三种密度2D-C/SiC复合材料力学性能

Table 1. Experimentally measured mechanical properties of 2D-C/SiC composite with three densities

Density ρ/(g·cm−3) Width/mm Thickness/mm Modulus/GPa Strength/MPa Fracture strain/10−6 Poisson ratio 1.82 15 3.6 123.55 233.27 3906 0.037 1.87 15 3.6 128.01 264.42 4076 0.049 2.00 15 3.6 146.42 280.56 4315 0.030 表 2 不同密度的2D-C/SiC 复合材料的声速特征

Table 2. Sound velocity characteristics of 2D-C/SiC composite with three densities

Density/(g·cm−3) Vmax/(m·s−1) Vmin/(m·s−1) ΔV/(m·s−1) 1.82 7785 6399 1386 1.87 7850 5900 1950 2.00 8134 5300 2834 表 3 三种不同密度的2D-C/SiC复合材料材料的最大损伤变量

Table 3. Maximum damage variables of 2D-C/SiC composite with three densities

Density/(g·cm−3) d1max/(m·s−1) d2max/(m·s−1) 1.82 0.395 0.310 1.87 0.428 0.376 2.00 0.572 0.438 -

[1] 薛建刚, 高希光, 方光武, 等. 针刺陶瓷基复合材料损伤本构模型及构件应力分析[J]. 航空动力学报, 2016, 30(10):2370-2375.XUE Jiangang, GAO Xiguang, FANG Guangwu, et al. A damage constitutive model for needled CMCs composites and stress analysis of components[J]. Journal of Aerospace Power,2016,30(10):2370-2375(in Chinese). [2] 潘文革, 矫桂琼, 管国阳. 二维机织碳纤维/碳化硅陶瓷基复合材料损伤分析[J]. 硅酸盐学报, 2005, 33(11):23-27.PAN Wenge, JIAO Guiqiong, GUAN Guoyang. Damage analysis of two-dimensional woven carbon fiber/silicon carbide ceramic matrix composites[J]. Journal of the Chinese Ceramic Society,2005,33(11):23-27(in Chinese). [3] 黄喜鹏, 王波, 杨成鹏, 等. 基于声发射信号的三维针刺C/SiC复合材料拉伸损伤演化研究[J]. 无机材料学报, 2018, 33(6):609-616. doi: 10.15541/jim20170355HUANG Xipeng, WANG Bo, YANG Chengpeng, et al. Evaluating damage evolution of three-dimension needled C/SiC composite based on acoustic emission signal analysis[J]. Journal of Inorganic Materials,2018,33(6):609-616(in Chinese). doi: 10.15541/jim20170355 [4] 黄喜鹏, 王波, 杨成鹏等. 基于声发射信号的不同密度C-SiC复合材料损伤演化研究[J]. 复合材料学报, 2019, 36(2):425-433.HUANG Xipeng, WANG Bo, YANG Chengpeng, et al. Damage evolution of C/SiC composite materials with different densities based on acoustic emission signal analysis[J]. Acta Materiae Compositae Sinica,2019,36(2):425-433(in Chinese). [5] 皇甫劭炜, 童小燕, 姚磊江, 等. 复合材料层合板损伤的声发射试验研究[J]. 机械科学与技术, 2009, 28(5):669-673.HUANGFU Shaowei, TONG Xiaoyan, YAO Leijiang, et al. A study of the damage of composite laminates under different types of loadings based on acoustic emission technology[J]. Mechanical Science and Technology for Aerospace Engineering,2009,28(5):669-673(in Chinese). [6] 常岩军, 矫桂琼, 张克实, 等. 3D C/SiC复合材料拉伸性能的声发射研究[J]. 复合材料学报, 2010, 27(6):82-87.CHANG Yanjun, JIAO Guiqiong, ZHANG Keshi, et al. Investigation on tensile properties for 3D C/SiC composites by acoustic emission[J]. Acta Materiae Compositae Sinica,2010,27(6):82-87(in Chinese). [7] MORSCHER G N, GYEKENYESI A L. The velocity and attenuation of acoustic emission waves in SiC/SiC composites loaded in tension[J]. Composites Science and Technology,2002,62(9):1171-1180. doi: 10.1016/S0266-3538(02)00065-9 [8] 梁天成, 葛洪魁, 郭志伟, 等. 利用声发射和波速变化判定岩石损伤状态[J]. 中国地震, 2012, 28(2):154-166.LIANG Tiancheng, GE Hongkui, GUO Zhiwei, et al. Evaluation of rock damage state with acoustic emission and velocity variation[J]. Earthquake Research in China,2012,28(2):154-166(in Chinese). [9] ALMANSOUR A, MAILLET E, RAMASAMY S, et al. Effect of fiber content on single tow SiC minicomposite mechanical and damage properties using acoustic emission[J]. Journal of the European Ceramic Society,2015,35(13):3389-3399. doi: 10.1016/j.jeurceramsoc.2015.06.001 [10] RODRÍGUEZ P, CELESTINO T B. Assessment of damage distribution in brittle materials by application of an improved algorithm for three-dimensional localization of acoustic emission sources with P-wave velocity calculation[J]. Construction and Building Materials,2019,231:117086. [11] MARGULIES T S, SCHWARZ W H. Acoustic wave propagation in anisotropic materials[J]. Journal of the Acoustical Society of America,1985,77(s1):S20. [12] 赵清望, 夏定海. 纤维增强复合材料弹性常数测定的平面声波相速法研究[J]. 上海机械学院学报, 1985(1):68-76.ZHAO Qingwang, XIA Dinghai. A research in phase velocity method of plane wave to determine the elastic constants for fiber reinforced composite materials[J]. Journal of University of Shanghai for Science and Technology,1985(1):68-76(in Chinese). [13] 矫桂琼, 贾普荣. 复合材料力学[M]. 西安: 西北工业大学出版社, 2008.JIAO Guiqiong, JIA Purong. Composite mechanics[M]. Xi’an: Northwestern Polytechnical University Press, 2008(in Chinese). [14] GORMAN M R. Plate wave acoustic emission[J]. Journal of the Acoustical Society of America,1991,90(1):358-364. doi: 10.1121/1.401258 [15] FABIAN B, DIETMAR K, EMMANUEL M, et al. Modal acoustic emission of damage accumulation in C/C–SiC composites with different fiber architectures[J]. Ceramics International,2015,41(9):12087-12098. doi: 10.1016/j.ceramint.2015.06.026 [16] 王波, 吴亚波, 郭洪宝, 等. 2D-C/SiC复合材料偏轴拉伸力学行为研究[J]. 材料工程, 2017, 45(7):91-96.WANG Bo, WU Yabo, GUO Hongbao, et al. Investigation on off-axis tensile mechanical behaviors of 2D-C/SiC composites[J]. Journal of Materials Engineering,2017,45(7):91-96(in Chinese). [17] MENG L, LI Y, WANG W, et al. Experimental study on leak detection and location for gas pipeline based on acoustic method[J]. Journal of Loss Prevention in the Process Industries,2012,25(1):90-102. doi: 10.1016/j.jlp.2011.07.001 [18] 王建强, 余龙, 张宇, 等. 基于最大相似性的Lamb波损伤信号分解及试验研究[J]. 振动与冲击, 2014, 33(24):200-204.WANG Jianqiang, YU Long, ZHANG Yu, et al. Damage signal decomposition of lamb wave and tests based on similarity[J]. Journal of Vibration and Shock,2014,33(24):200-204(in Chinese). [19] PARK W H, PACKO P, KUNDU T. Acoustic source localization in an anisotropic plate without knowing its material properties: A new approach[J]. Ultrasonics,2017,79:9-17. doi: 10.1016/j.ultras.2017.02.021 [20] 谢惠贞, 孙建涛, 何轩宇, 等. 密度对C/C复合材料热力学性能的影响[J]. 材料导报, 2018, 32(2): 268-271, 277.XIE Huizhen, SUN Jiantao, HE Xaunyu, et al. Influence of density on mechanical and thermal performance of C/C composite[J]. Material Review, 2018, 32(2): 268-271, 277(in Chinese). [21] 李潘, 王波, 甄文强, 等. 2D SiC/SiC复合材料拉伸加卸载行为[J]. 复合材料学报, 2014, 31(3):676-682.LI Pan, WANG Bo, ZHEN Wenqiang, et al. Tensile lolding/unloading stress-strain behavior of 2D-SiC/SiC composites[J]. Acta Materia Compositae Sinica,2014,31(3):676-682(in Chinese). [22] KIM R Y, PAGANO N J. Crack initiation in unidirectional brittle matrix composites[J]. Journal of the American Ceramic Society,1991,74(5):1082-1090. doi: 10.1111/j.1151-2916.1991.tb04346.x [23] LUO Y J, CHANG S C, DANIEL I M. Acoustic emission study of failure mechanisms in ceramic matrix composites under longitudinal tensile loading[J]. Journal of Composite Materials,1995,29(15):1946-1961. doi: 10.1177/002199839502901501 [24] MORSCHER G, SINGH M, KISER J, et al. Modeling stress-dependent matrix cracking and stress-strain behavior in 2D woven SiC fiber reinforced CVI SiC composites[J]. Composites Science and Technology,2007,67(6):1009-1017. doi: 10.1016/j.compscitech.2006.06.007 -

下载:

下载: