| [1] |

HE Q C, LI H J, WANG C C, et al. Microstructure and ablation property of gradient ZrC-SiC modified C/C composites prepared by chemical liquid vapor deposition[J]. Ceramics International,2019,45(10):13283-13296. doi: 10.1016/j.ceramint.2019.04.018

|

| [2] |

李贺军, 史小红, 沈庆凉, 等. 国内C/C复合材料研究进展[J]. 中国有色金属学报, 2019, 29(9):2142-2154.LI H J, SHI X H, SHEN Q L, et al. Research and development of C/C composites in China[J]. The Chinese Journal of Nonferrous Metals,2019,29(9):2142-2154(in Chinese).

|

| [3] |

HE Q C, LI H J, YIN X M, et al. Microstructure, mechanical and anti-ablation properties of SiCnw/PyC core-shell networks reinforced C/C-ZrC-SiC composites fabricated by a multistep method of chemical liquid-vapor deposition[J]. Ceramics International,2019,45(16):20414-20426. doi: 10.1016/j.ceramint.2019.07.018

|

| [4] |

KOGO Y, KIKKAWA A, SAITO W, et al. Comparative study on tensile fracture behavior of monofilament and bundle C/C composites[J]. Composites Part A: Applied Science and Manufacturing,2006,37(12):2241-2247. doi: 10.1016/j.compositesa.2005.12.015

|

| [5] |

HATTA H, SUZUKI K, SHIGEI T, et al. Strength improvement by densification of C/C composites[J]. Carbon,2001,39(1):83-90. doi: 10.1016/S0008-6223(00)00083-X

|

| [6] |

ZHANG J, LUO R, XIANG Q, et al. Compressive fracture behavior of 3D needle-punched carbon/carbon composites[J]. Materials Science and Engineering A,2011,528(15):5002-5006. doi: 10.1016/j.msea.2011.03.055

|

| [7] |

LI D, YAO Q, JIANG N, et al. Bend properties and failure mechanism of a carbon/carbon composite with a 3D needle-punched preform at room and high temperatures[J]. New Carbon Materials,2016,31(4):437-444. doi: 10.1016/S1872-5805(16)60023-9

|

| [8] |

BRADLEY L R, BOWEN C R, MCENANEY B, et al. Shear properties of a carbon/carbon composite with non-woven felt and continuous fibre reinforcement layers[J]. Carbon,2007,45(11):2178-2187. doi: 10.1016/j.carbon.2007.06.072

|

| [9] |

张伟, 庞宝君, 张泽华, 等. 航天器波纹防护屏高速撞击实验研究[J]. 宇航学报, 2000, 21(1):79-84. doi: 10.3321/j.issn:1000-1328.2000.01.013ZHANG W, PANG B J, ZHANG Z H, et al. High-velocity impact experimental investigation of spacecraft corrugated bumper shielding[J]. Journal of Astronautics,2000,21(1):79-84(in Chinese). doi: 10.3321/j.issn:1000-1328.2000.01.013

|

| [10] |

NARESH K, SHANKAR K, RAO B S, et al. Effect of high strain rate on glass/carbon/hybrid fiber reinforced epoxy laminated composites[J]. Composites Part B: Engineering,2016,100:125-135. doi: 10.1016/j.compositesb.2016.06.007

|

| [11] |

WANG M, ZHANG P W, FEI Q G. Transverse properties prediction of polymer composites at high strain rates based on unit cell model[J]. Journal of Aerospace Engineering,2017,31(2):04017102.

|

| [12] |

吴以婷, 葛东云, 李辰. 湿热环境下 Carbon/Epoxy 复合材料层合板动态压缩性能[J]. 复合材料学报, 2016, 33(2):259-264.WU Y T, GE D Y, LI C. Dynamic compressive properties of Carbon/Epoxy laminates under hygrothermal environment[J]. Acta Materiae Compositae Sinica,2016,33(2):259-264(in Chinese).

|

| [13] |

GAO Y B, TANG T G, YI C H, et al. Study of static and dynamic behavior of TiB2-B4C composite[J]. Materials and Design,2016,92:814-822;. doi: 10.1016/j.matdes.2015.12.123

|

| [14] |

XIE W B, ZHANG W, KUANG N H, et al. Experimental investigation of normal and oblique impacts on CFRPs by high velocity steel sphere[J]. Composites Part B: Engineering,2016,99:483-493. doi: 10.1016/j.compositesb.2016.06.020

|

| [15] |

HUANG W, ZHANG W, CHEN T, et al. Dynamic response of circular composite laminates subjected to underwater impulsive loading[J]. Composites Part A: Applied Science and Manufacturing, 2018, 109: 63-74.

|

| [16] |

YUAN Q L, LI Y L, LI H J, et al. Quasi-static and dynamic compressive fracture behavior of carbon/carbon composites[J]. Carbon,2008,46(4):699-703. doi: 10.1016/j.carbon.2008.01.031

|

| [17] |

袁秦鲁, 李玉龙, 李贺军, 等. C/C复合材料压缩破坏的应变率效应研究[J]. 无机材料学报, 2007, 22(2):311-314. doi: 10.3321/j.issn:1000-324X.2007.02.024YUAN Q L, LI Y L, LI H J, et al. Strain rate sensitivity of C/C composites under compression[J]. Journal of Inorganic Materials,2007,22(2):311-314(in Chinese). doi: 10.3321/j.issn:1000-324X.2007.02.024

|

| [18] |

LI D S, DUAN H W, WANG W, et al. Strain rate and temperature effect on mechanical properties and failure of 3D needle-punched carbon/carbon composites under dynamic loading[J]. Composite Structures,2017,172:229-241. doi: 10.1016/j.compstruct.2016.11.082

|

| [19] |

LAN F T, LI K Z, LI H J, et al. Joining of carbon/carbon composites for nuclear applications[J]. Journal of Materials Science,2009,44(14):3747-3750. doi: 10.1007/s10853-009-3501-0

|

| [20] |

ZHOU Y D, FEI Q G, TAO J Y. Profile design of loaded pins in composite single lap joints: From circular to non-circular[J]. Results in Physics,2016,6:471-480. doi: 10.1016/j.rinp.2016.07.010

|

| [21] |

ZHOU Y D, FEI Q G. Evaluation of opening-hole shapes for rivet connection of a composite plate[J]. Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science,2017,231(20):3810-3817. doi: 10.1177/0954406216652169

|

| [22] |

ZHOU Y D, HANG X C, WU S Q, et al. Frequency-dependent random fatigue of panel-type structures made of ceramic matrix composites[J]. Acta Mechanica Solida Sinica,2017,30(2):165-173. doi: 10.1016/j.camss.2017.03.010

|

| [23] |

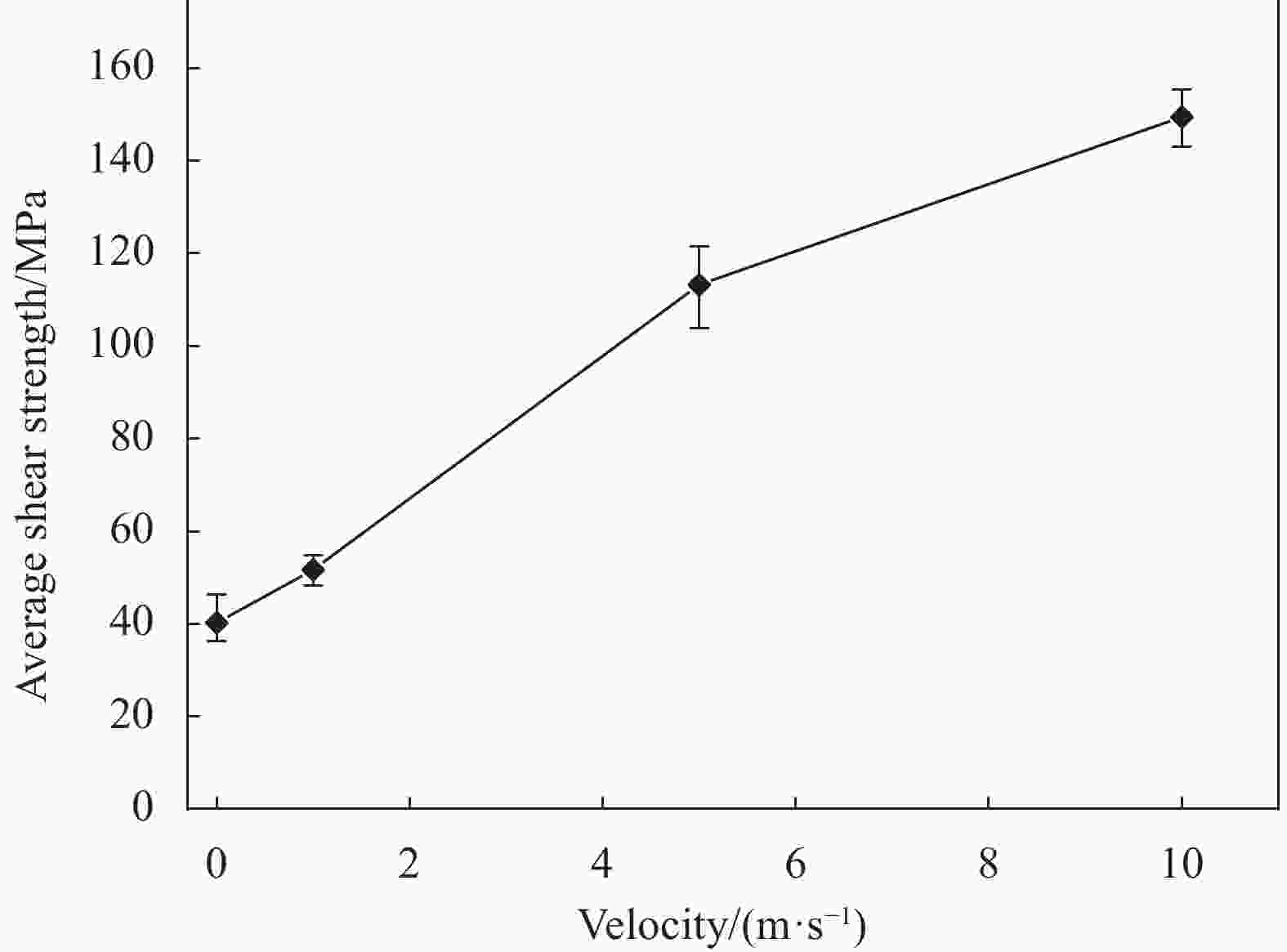

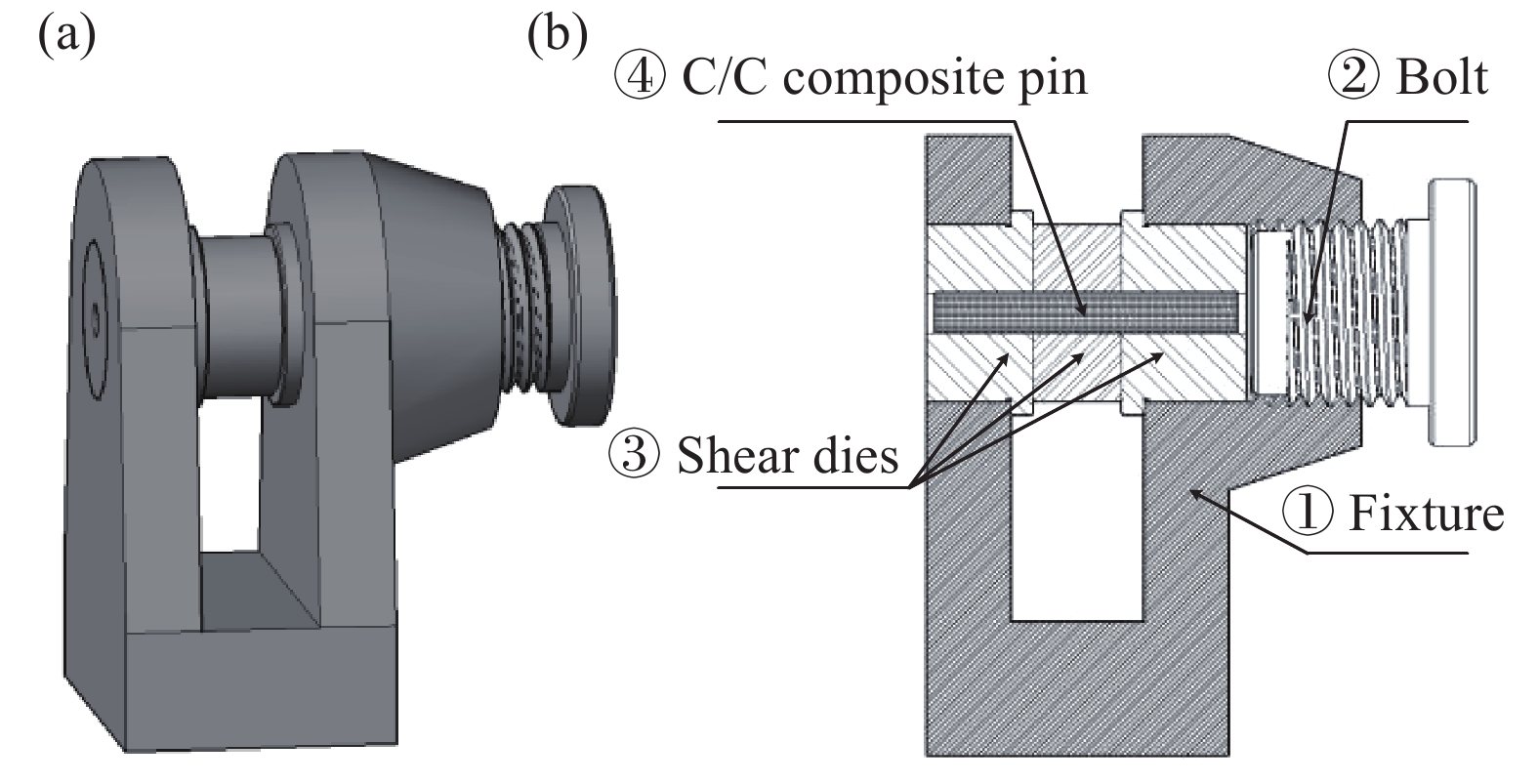

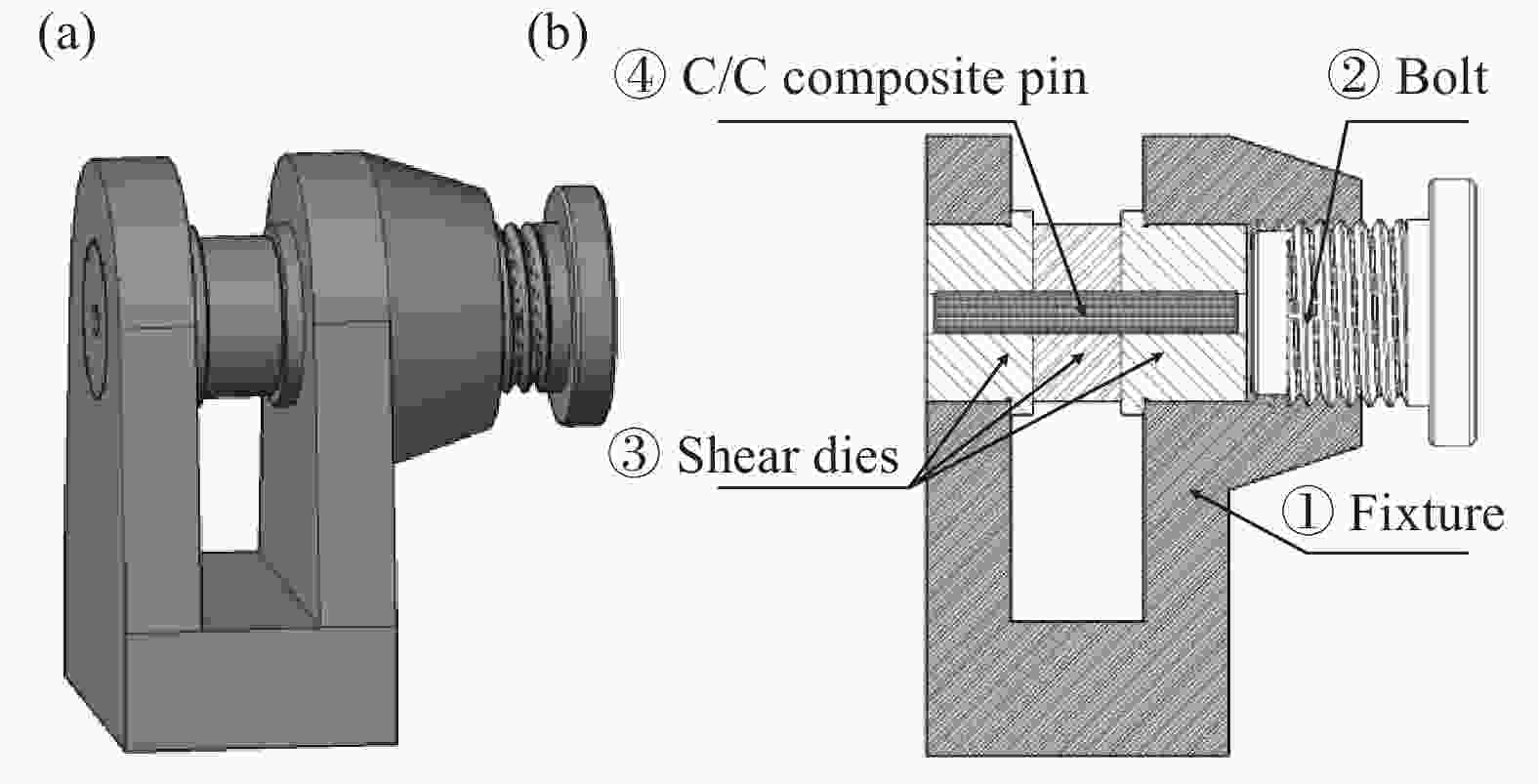

GUO F, FEI Q G, LI Y B, et al. Novel statistical analysis method for determining shear strength of C/C composite pin[J]. Ceramics International,2020,46(4):5262-5270. doi: 10.1016/j.ceramint.2019.10.275

|

| [24] |

郭飞, 费庆国, 李彦斌, 等. 基于 Weibull 模型的 C/C 复合材料销钉剪切强度分布及本构关系[J]. 复合材料学报, 2019, 36(2):461-468.GUO F, FEI Q G, LI Y B, et al. Shear strength distribution and constitutive model of C/C composite pins based on Weibull model[J]. Acta Materiae Compositae Sinica,2019,36(2):461-468(in Chinese).

|

| [25] |

王杰, 李克智, 郭领军, 等. 炭布叠层穿刺C/C复合材料螺栓连接件微观组织和力学性能[J]. 固体火箭技术, 2012, 35(2):248-252. doi: 10.3969/j.issn.1006-2793.2012.02.022WANG J, LI K Z, GUO L J, et al. Microstructure and mechanical properties of C/C composite bolts[J]. Journal of Solid Rocket Technology,2012,35(2):248-252(in Chinese). doi: 10.3969/j.issn.1006-2793.2012.02.022

|

| [26] |

ASTM International. Standard test method for shear testing of aluminum alloys: ASTM B769—11[S]. West Conshohocken: ASTM International, 2016.

|

下载:

下载: