An evaluation method for uncertainty in failure load of CFRP composite bolted joints

-

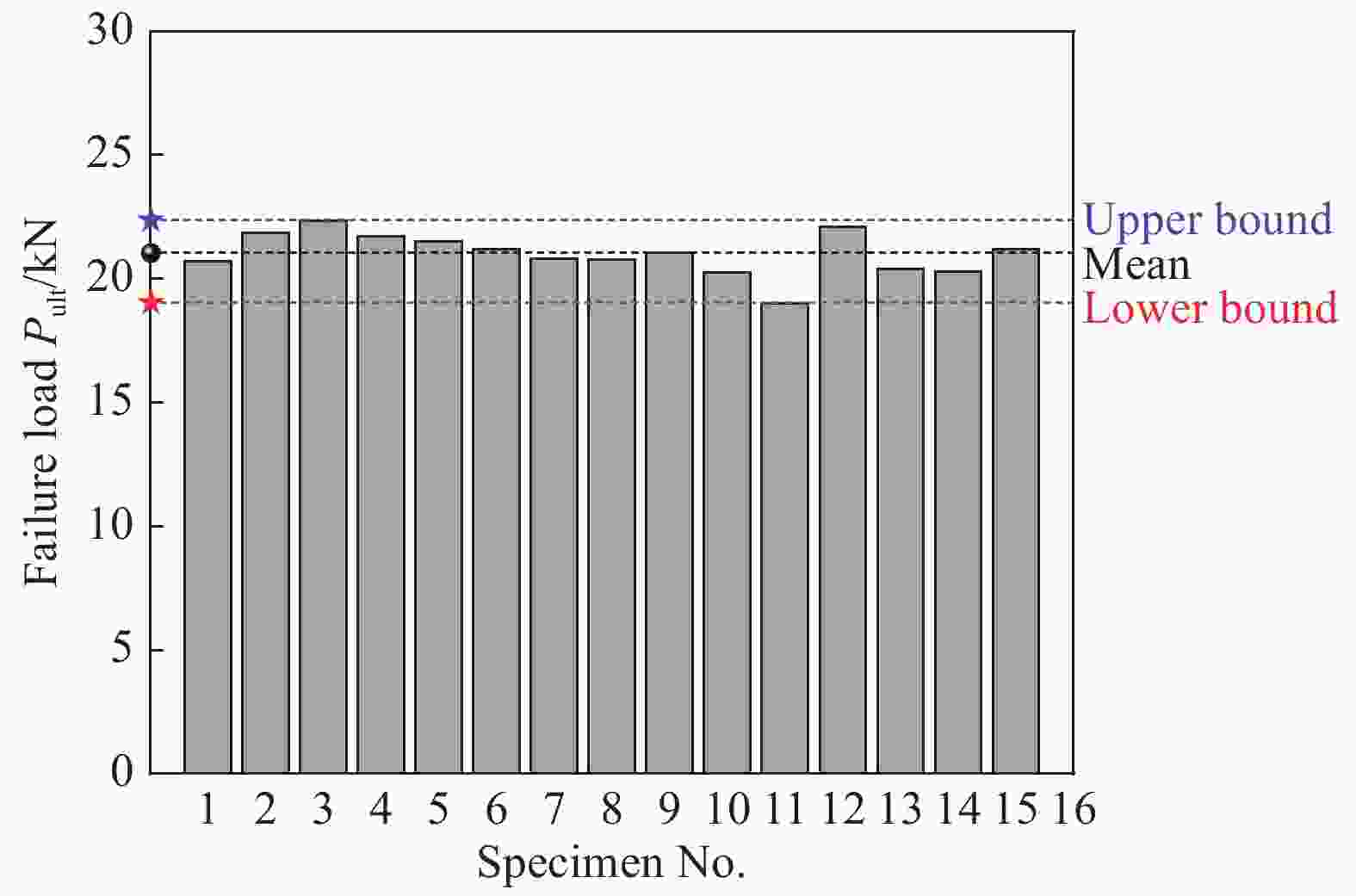

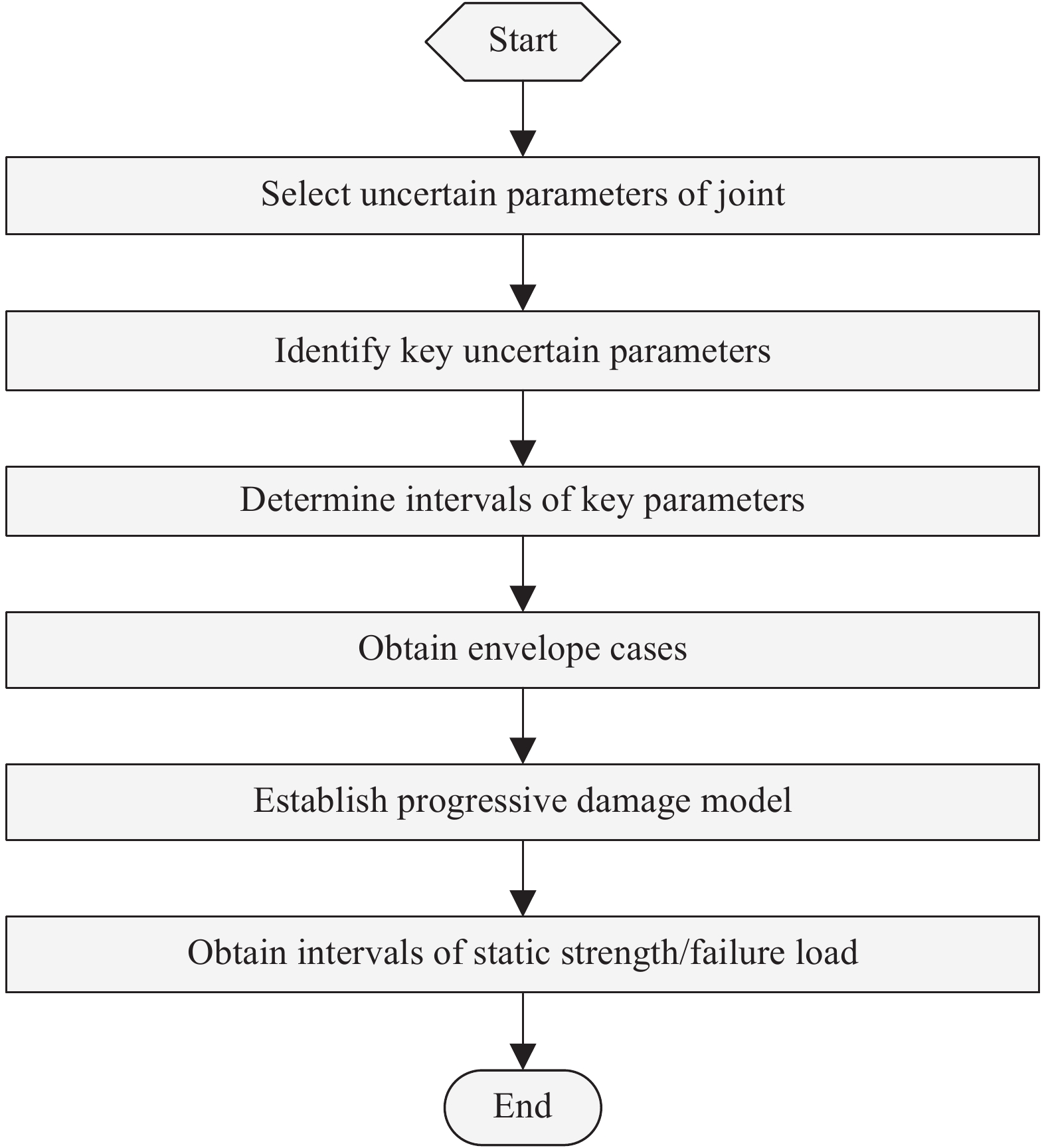

摘要: 螺栓连接是先进复合材料结构的薄弱环节。因此,螺栓连接力学性能显著的不确定性不仅阻碍了先进复合材料的高效应用,且给整体结构的安全性和可靠性带来威胁。为定量评估碳纤维增强树脂(CFRP)复合材料螺栓连接失效载荷的不确定性,将数值的渐进损伤模型和区间分析方法结合,提出了一种高效、准确的分析方法。采用该方法预测了典型T800碳纤维/X850环氧树脂复合材料螺栓连接失效载荷的不确定性,并与试验结果进行对比。预测结果与试验结果的误差不超过2%,证明本文所提出方法的有效性。采用本文所提方法预测的T800碳纤维/X850环氧树脂复合材料螺栓连接失效载荷的区间为[19.25 kN, 22.75 kN],与设计期望值的偏差为[−9.8%, 6.6%]。Abstract: Bolted joints are the weak points of composite structures. Therefore, the considerable uncertainty in mechanical properties of the bolted joints not only prevents advanced composites from efficient applications, but also threatens the safety and reliability of the structures. In order to quantitatively evaluate the uncertainty in failure load of carbon fiber reinforced polymer (CFRP) composite bolted joints, an efficient and accurate analysis method was proposed based on the numerical progressive damage model and interval analysis method. The proposed method was used to predict the uncertain failure load of T800 carbon fiber/X850 epoxy composite bolted joint. The predicted results were compared with the experimental outcome. The small error less than 2% between the predicted and experimental results validates the effectiveness of the proposed method. According to the predicted results, the interval of failure load of the T800 carbon fiber/X850 epoxy composite bolted joint is [19.25 kN, 22.75 kN] with the deviations from the design expected values of [−9.8%, 6.6%].

-

Key words:

- CFRP composite /

- bolted joint /

- failure load /

- uncertainty /

- progressive damage model /

- interval analysis

-

表 2 T800碳纤维/X850环氧树脂复合材料基本力学性能的平均值

Table 2. Means of basic material properties of T800 carbon fiber/X850 epoxy composites

Elastic parameter E11 E22 G12 ν12 Value/GPa 195 8.58 4.57 0.33 Strength parameter XT XC YT YC S12 Value/MPa 3071 1747 88 271 143 Notes: E11—Longitudinal elastic modulus; E22—Transverse elastic modulus; G12—Longitudinal transverse shear modulus; ν12—Longitudinal transverse Poisson’s ratio; XT—Longitudinal tensile strength; XC—Longitudinal compressive strength; YT—Transverse tensile strength; YC—Transverse compressive strength; S12—Longitudinal transverse shear strength. 表 1 T800碳纤维/X850环氧树脂复合材料层压板几何尺寸和铺层角度

Table 1. Geometrical dimensions and fiber orientation angles of T800 carbon fiber/X850 epoxy composite laminate

Geometrical dimension w Sw e D tply Value/mm 30 15 15 4.76 0.185 Fiber orientation angle θ1 θ2 θ3 θ4 Value/(°) 0 90 45 −45 Notes: w—Width of laminate; Sw—Edge distance of laminate; e—End distance of lamiante; D—Diameter of hole in laminate; tply—Thickness of laminate; θ1, θ2, θ3, θ4—Fiber orientation angles of laminate. 表 3 影响T800碳纤维/X850环氧树脂复合材料螺栓连接失效载荷的关键参数的区间

Table 3. Intervals of key parameters affecting failure load of T800 carbon fiber/X850 epoxy composite bolted joint

Variable X Normal distribution[16] Interval μ σ [μ−3σ, μ+3σ] XC/MPa 1747 65.8 [1550, 1944] tply/mm 0.185 0.004 [0.173, 0.197] E11/GPa 195 3.8 [184, 206] Notes: µ—Expected value of normal distribution; σ—Standard deviation of normal distribution. 表 4 T800碳纤维/X850环氧树脂复合材料螺栓连接失效载荷Pult不确定性的计算方案

Table 4. Calculation scheme for uncertain failure load Pult of T800 carbon fiber/X850 epoxy composite bolted joint

Case XC/MPa tply/mm E11/GPa Pult/kN A 1747 0.185 195 Expected B 1550 0.173 206 Lower bound C 1944 0.197 184 Upper bound 表 5 单向纤维增强树脂复合材料的材料性能退化模型

Table 5. Material property degradation model of unidirectional fiber reinforced resin composites

Failure mode Degradation scheme Fiber tension $E_{11}^{\rm{d}} = {d_{{\rm{ft}}}}{E_{11}}$ Fiber compression $E_{11}^{\rm{d}} = {d_{{\rm{fc}}}}{E_{11}}$ Matrix tension $E_{{\rm{22}}}^{\rm{d}} = {d_{{\rm{mt}}}}{E_{22}}$, $G_{{\rm{12}}}^{\rm{d}} = {d_{{\rm{mt}}}}{G_{12}}$, $G_{{\rm{23}}}^{\rm{d}} = {d_{{\rm{mt}}}}{G_{23}}$, $\nu _{{\rm{12}}}^{\rm{d}} = {d_{{\rm{mt}}}}{\nu _{12}}$, $\nu _{{\rm{23}}}^{\rm{d}} = {d_{{\rm{mt}}}}{\nu _{23}}$ Matrix compression $E_{{\rm{22}}}^{\rm{d}} = {d_{{\rm{mc}}}}{E_{22}}$, $G_{{\rm{12}}}^{\rm{d}} = {d_{{\rm{mc}}}}{G_{12}}$, $G_{{\rm{23}}}^{\rm{d}} = {d_{{\rm{mc}}}}{G_{23}}$, $\nu _{{\rm{12}}}^{\rm{d}} = {d_{{\rm{mc}}}}{\nu _{12}}$, $\nu _{{\rm{23}}}^{\rm{d}} = {d_{{\rm{mc}}}}{\nu _{23}}$ Fiber-matrix shear-out $G_{{\rm{12}}}^{\rm{d}} = {d_{{\rm{fm1}}}}{G_{12}}$, $G_{{\rm{13}}}^{\rm{d}} = {d_{{\rm{fm1}}}}{G_{13}}$, $G_{{\rm{23}}}^{\rm{d}} = {d_{{\rm{fm2}}}}{G_{23}}$, $\nu _{{\rm{12}}}^{\rm{d}} = {d_{{\rm{fm1}}}}{\nu _{12}}$, $\nu _{{\rm{13}}}^{\rm{d}} = {d_{{\rm{fm1}}}}{\nu _{13}}$, $\nu _{{\rm{23}}}^{\rm{d}} = {d_{{\rm{fm2}}}}{\nu _{23}}$ Interlaminar tension $E_{{\rm{33}}}^{\rm{d}} = {d_{{\rm{dt}}}}{E_{33}}$, $G_{{\rm{13}}}^{\rm{d}} = {d_{{\rm{dt}}}}{G_{13}}$, $G_{{\rm{23}}}^{\rm{d}} = {d_{{\rm{dt}}}}{G_{23}}$, $\nu _{{\rm{13}}}^{\rm{d}} = {d_{{\rm{dt}}}}{\nu _{13}}$, $\nu _{{\rm{23}}}^{\rm{d}} = {d_{{\rm{dt}}}}{\nu _{23}}$ Interlaminar compression $E_{{\rm{33}}}^{\rm{d}} = {d_{{\rm{dc}}}}{E_{33}}$, $G_{{\rm{13}}}^{\rm{d}} = {d_{{\rm{dc}}}}{G_{13}}$, $G_{{\rm{23}}}^{\rm{d}} = {d_{{\rm{dc}}}}{G_{23}}$, $\nu _{{\rm{13}}}^{\rm{d}} = {d_{{\rm{dc}}}}{\nu _{13}}$, $\nu _{{\rm{23}}}^{\rm{d}} = {d_{{\rm{dc}}}}{\nu _{23}}$ 表 6 T800碳纤维/X850环氧树脂复合材料螺栓连接失效载荷的区间及相对设计期望值的偏差

Table 6. Intervals and deviations of predicted and experimental failure loads of T800 carbon fiber/ X850 epoxy composite bolted joint

Case Interval/[kN, kN] Deviation from expected Experimental [19.00, 22.34] [−9.6%, 6.3%] Predicted [19.25, 22.75] [−9.8%, 6.6%] -

[1] MCCARTHY M. BOJCAS: Bolted joints in composite aircraft structures[J]. Air & Space Europe,2001,3(3-4):139-142. [2] MANGALGIRI P D. Design allowable considerations for use of laminated composites in aircraft structures[J]. Journal of the Indian Institute of Science,2013,93(4):571-592. [3] ATAS A, SOUTIS C. Damage and failure analysis of bolted joints in composite laminates[M]//BEAUMONT P W R, SOUTIS C, HODZIC A. The Structural Integrity of Carbon Fiber Composites. Springer International Publishing, 2017: 591-644. [4] 赵丽滨, 刘丰睿, 黄伟, 等. 复合材料螺栓连接失效分析研究进展[J]. 强度与环境, 2017, 44(3):1-11.ZHAO L B, LIU F R, HUANG W, et al. Advances in failure analysis methods of bolted composite joints[J]. Structure & Environment Engineering,2017,44(3):1-11(in Chinese). [5] 岳烜德, 安鲁陵, 云一珅, 等. 液体垫片对复合材料单搭接螺栓接头力学性能的影响[J]. 复合材料学报, 2018, 35(1):50-60.YUE X D, AN L L, YUN Y S, et al. Influence of the liquid shim on the mechanical properties of single-lap composite bolted joint[J]. Acta Materiae Compositae Sinica,2018,35(1):50-60(in Chinese). [6] SOARES C G. Reliability of components in composite materials[J]. Reliability Engineering and System Safety,1997,55(2):171-177. doi: 10.1016/S0951-8320(96)00008-7 [7] CHIACHIO M, CHIACHIO J, RUS G. Reliability in composites: A selective review and survey of current development[J]. Composites Part B: Engineering,2012,43(3):902-913. doi: 10.1016/j.compositesb.2011.10.007 [8] 王佩艳, 朱振涛, 王富生, 等. 复合材料螺栓连接性能的分散性和可靠性分析[J]. 力学季刊, 2008, 29(4):573-577.WANG P Y, ZHU Z T, WANG F S, et al. Dispersibility and reliability analysis of composite laminates bolted joint[J]. Chinese Quarterly of Mechanics,2008,29(4):573-577(in Chinese). [9] KHASHABA U A, SEBAEY T A, ALNEFAIE K A. Failure and reliability analysis of pinned-joint composite laminates: Effects of pin-hole clearance[J]. Journal of Composite Materials,2013,47(18):2287-2298. doi: 10.1177/0021998312457196 [10] KHASHABA U A, SEBAEY T A, ALNEFAIE K A. Failure and reliability analysis of pinned-joints composite laminates: Effects of stacking sequences[J]. Composites Part B: Engineering,2013,45(1):1694-1703. [11] LI H S, LU Z Z, ZHANG Y. Probabilistic strength analysis of bolted joints in laminated composites using point estimate method[J]. Composite Structures,2009,88(2):202-211. doi: 10.1016/j.compstruct.2008.03.040 [12] LI H S. Maximum entropy method for probabilistic failure load prediction of pin joints in composite laminates[J]. Composite Structures,2013,106:626-634. doi: 10.1016/j.compstruct.2013.05.040 [13] LI H S, XIA S, LUO D M. A probabilistic analysis for pin joint failure load in composite laminates using Subset Simulation[J]. Composites Part B: Engineering,2014,56:780-789. doi: 10.1016/j.compositesb.2013.09.025 [14] NAKAYAMA M, UDA N, ONO K. Probabilistic assessment of pin joint strength in CFRP laminates[J]. Composite Structures,2011,93(8):2026-2030. doi: 10.1016/j.compstruct.2011.02.019 [15] NAKAYAMA M, UDA N, ONO K, et al. Design-oriented strength of mechanical joints in composite laminate structures and reliability-based design factor[J]. Composite Structures,2015,132:1-11. doi: 10.1016/j.compstruct.2015.04.044 [16] ZHAO L, SHAN M, LIU F, et al. A probabilistic model for strength analysis of composite double-lap single-bolt joints[J]. Composite Structures,2017,161:419-427. doi: 10.1016/j.compstruct.2016.11.074 [17] LIU F, FANG Z, ZHAO L, et al. A failure-envelope-based method for the probabilistic failure prediction of composite multi-bolt double-lap joints[J]. Composites Part B: Engineering,2019,172:593-602. doi: 10.1016/j.compositesb.2019.05.034 [18] 左健巍. 复合材料结构的重要性测度[C]//第四届中国航空科学技术大会论文集. 中国航空学会, 2019: 264-277.ZUO J W. Importance measure on composite material structures[C]//Proceedings of the 4th China Aviation Science and Technology Conference. Chinese Society of Aeronautics and Astronautics, 2019: 264-277(in Chinese). [19] 高魁垠, 李海波, 吴建国, 等. 2D-C/SiC复合材料螺栓连接结构可靠性分析[J]. 强度与环境, 2020, 47(1):33-40.GAO K Y, LI H B, WU J G, et al. Reliability analysis of 2D-C/SiC composite bolted joints[J]. Structure & Environment Engineering,2020,47(1):33-40(in Chinese). [20] ASKRI R, BOIS C, WARGNIER H, et al. Tolerance synthesis of fastened metal-composite joints based on probabilistic and worst-case approaches[J]. Computer-Aided Design,2018,100:39-51. doi: 10.1016/j.cad.2018.02.008 [21] 黄河源, 赵美英, 万小朋, 等. 复合材料中厚板沉头连接结构强度与损伤失效[J]. 复合材料学报, 2017, 34(3):557-563.HUANG H Y, ZHAO M Y, WAN X P, et al. Strength and damage evolution of mid-thick composite laminates with countersunk bolt joints[J]. Acta Materiae Compositae Sinica,2017,34(3):557-563(in Chinese). [22] 刘志明, 许昶. 碳纤维增强环氧树脂复合材料与铝板胶螺混合连接接头失效仿真[J]. 复合材料学报, 2019, 36(10):2308-2315.LIU Z M, XU C. Failure simulation of carbon fiber reinforced epoxy resin composite-aluminum bonded-bolted hybrid joint[J]. Acta Materiae Compositae Sinica,2019,36(10):2308-2315(in Chinese). [23] 何柏灵, 葛东云. 复合材料连续损伤力学模型在螺栓接头渐进失效预测中的应用[J]. 复合材料学报, 2020, 37(8):2065-2075. doi: 10.13801/j.cnki.fhclxb.20191030.004HE B L, GE D Y. Application of continuum damage mechanics model for composites in progressive damage failure prediction of bolted joints[J]. Acta Materiae Compositae Sinica,2020,37(8):2065-2075(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191030.004 [24] ALAZWARI M A, RAO S S. Interval-based uncertainty models for micromechanical properties of composite materials[J]. Journal of Reinforced Plastics and Composites,2018,37(18):1142-1162. doi: 10.1177/0731684418788733 [25] TSERPES K I, LABEAS G, PAPANIKOS P, et al. Strength prediction of bolted joints in graphite/epoxy composite laminates[J]. Composites Part B: Engineering,2002,33(7):521-529. doi: 10.1016/S1359-8368(02)00033-1 [26] ZHANG J, ZHOU L, CHEN Y, et al. A micromechanics-based degradation model for composite progressive damage analysis[J]. Journal of Composite Materials,2016,50(16):2271-2287. doi: 10.1177/0021998315602947 -

下载:

下载: